Description

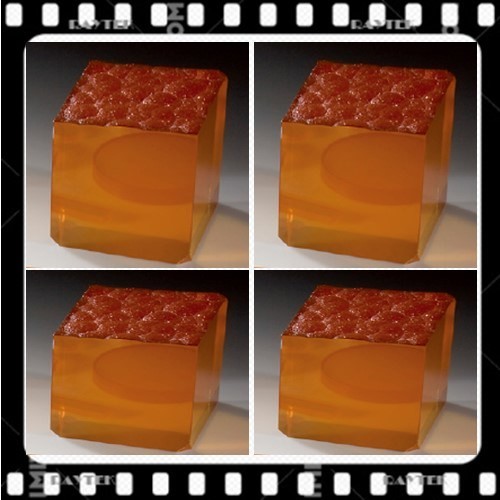

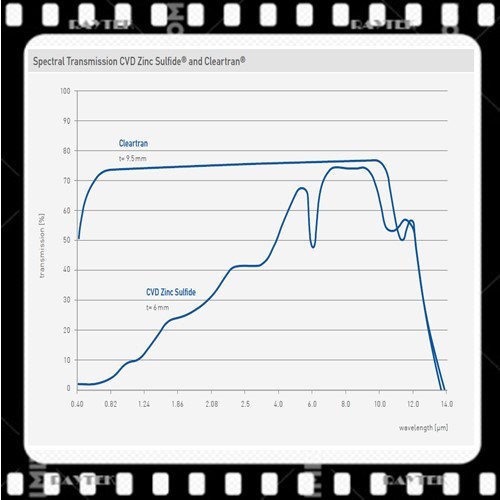

CVD Ceramics' chemically vapor deposited CVD Zinc Sulfide is the low cost alternative for infrared windows, domes and optical elements. With a fracture strength double that of zinc Sulfide and high hardness, zinc sulfide has been used successfully in many military applications requiring mechanical resistance to hostile environments. Cleartran is a form of CVD Zinc Sulfide material that is modified by a post-deposition hot isostatic process. This process removes zinc hydrides from the crystal lattice, normalizes crystal structure and purifies the material, all contributing to single crystal-like transmittance in the visible through far infrared ranges (0.35 -14 microns). With its low absorption and scatter throughout its broad transmitting range and high optical quality, is particularly well-suited for multi-spectral applications that require a single aperture for beam path for several wavebands.

CVD Zinc Sulfide and Cleartran are chemically inert, non-hygroscopic, highly pure, theoretically dense and easily machined.

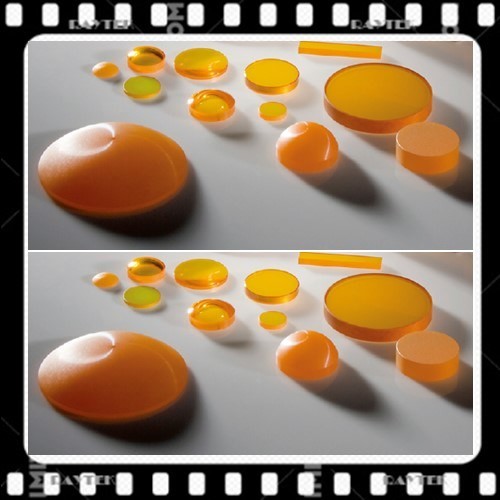

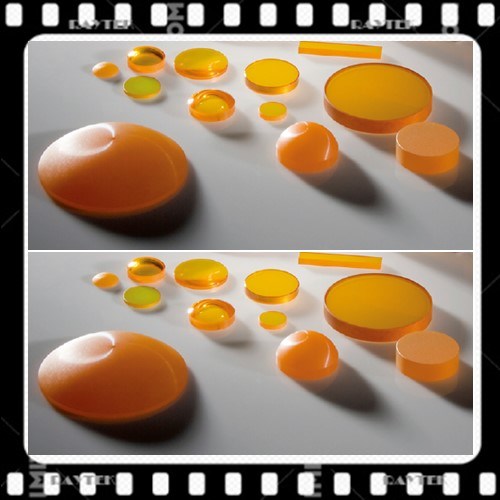

Custom diameters, rectangles, CNC-profiled blanks, generated lens blanks, prisms and near-net shape domes can be made to your specifications.

CVD Zinc Sulfide usually is used in VIS/IR applications

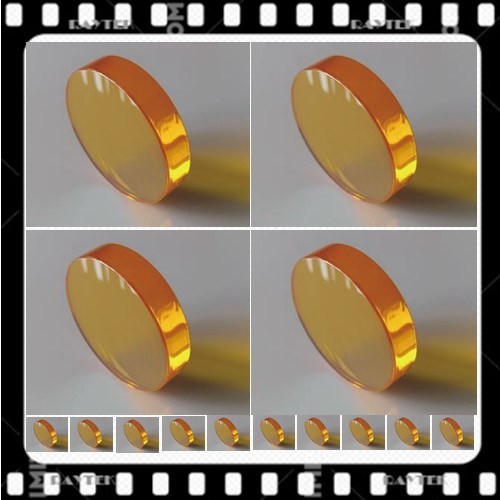

Products Name: CVD Zinc Sulfide

Alias: CVD Zinc Sulfide, Zinc Sulfide, Hellma Zinc Sulfide, Hellma CVD Zinc Sulfide, Hellma ZnS, Hellma ZnS materials, Hellma ZnS IR materials, Zinc Sulfide IR glass, ZnS IR glass, ZnS Optical Widnows, Hellma Zinc Sulfide Infrared materials, ZnS Infrared materials, ZnS Cleartran, Hellma ZnS Cleartran, CVD ZnS, CVD Zns materials,etc.

, etc.

Main Characteristics:

1).Its breaking strength is twice that of ZnSe, and its hardness is very high;

2).Excellent mechanical properties make it highly resistant to rain and dust

3).Its low cost also makes it very attractive for business and application

4).The chemical properties of CVD ZnS are inert

5).It has non hygroscopicity and high purity

6).Theoretically very compact and easy to machine

7).Same to ZnSe, ZnS exhibits high refractive uniformity and provides imaging uniformity over the entire 8-12 micron band

8).This kind of material can also transmit in the medium wave IR region, but with the increase of wave number, its absorption and scattering begin to increase

9).It can be used as a source of evaporation

10).It can maintain its stability under almost all environmental conditions.

11).Round blanks and sheets are available in stock to meet your urgent needs

Thermal Properties:

Mechanical Properties:

Optical Properties:

Main Applying Fields:

Matching Custom Manufacturing Serivce:

Including Moulding, CNC machining, Polishing, Particle beam processing, Magnetic flux conversion processing, Grinding, Coating, Lightweighting, Custom Shaping, Counterbores, Drilling & Coring, Edge & Bevel Polishing,3D Contouring, Bevels & Chamfers, Steps & Slots, Laser Cutting & Marking, Metrology & Inspection, Precision Pitch Polishing, Double-Sided Polishing, Optical Assembly, Measuring, etc.

Matching processing equipments;

1).Single side lapping and polishing machines

2).Duble sided polishing machines

3).Ring throwing machines

4).DMG five-axis five-linkage spherical milling machine

5).DMG ultrasonic machining center

6).Super large scale gantry cnc machining center (2.0*2.0m)

7).Super large scale surface grinder (1.6m*1.6m)

8).CNC cutting machines

9).Thin plate cleaning machines

10).Ultrasonic trough cleaning machines

11).Plane interferometers

12).Two dimensional detectors

13).Ion beam polishing machines

14).Magnetorheological polishing equipments

Main Cooperation Materials Manufacturers:

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETC

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Raytekoptics Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products with "3R" policy--return, replace & refund policy.

For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.