Description

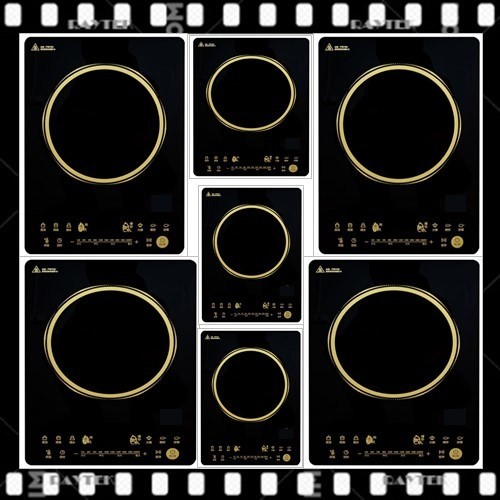

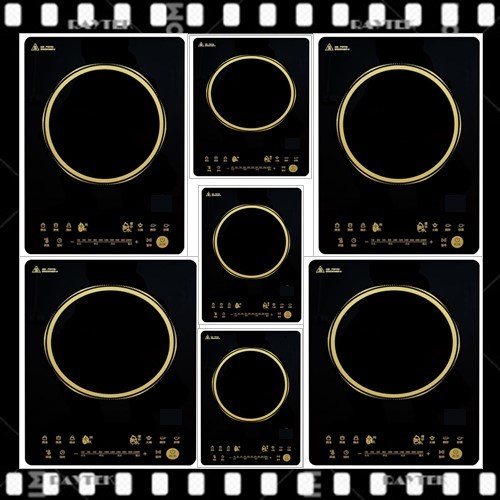

General Introduction: The glass-ceramic panel of induction cooker has the ability of resisting mechanical shock and hot and cold shock.

Glass ceramics is a kind of material made by crystallization of glass. In manufacturing, it needs to melt a kind of glass first, then add special ingredients, then blow, press, inject and pull it, and finally carry out heat treatment, so as to crystallization. It has a wide range of uses, because of its low expansion coefficient, high temperature resistance, high corrosion resistance, not easy to damage and long service life.

The glass ceramic panel of electromagnetic furnace is a kind of mixture of glass ceramics and glass made by sintering and crystallization of appropriate glass particles. The material is hard, dense and uniform, and there is no pollution in the production process. The product itself has no radioactive pollution. It is a new type of environmental protection green material.

The quality indexes of the glass ceramics panel in electromagnetic furnace (high hardness, corrosion resistance, compression resistance, impact resistance, non water absorption, less dust, no radiation) are better than natural stone plate. Adding different inorganic colorants in the raw materials can produce a variety of colors, uniform tone or colorful products. After polishing, the surface of the plate has the pattern or color grain of imitating natural stone. What is more valuable is its crystal clear and soft luster, and it has glass like crystal clear and bright optical effect under the sun.

Products Name: Induction glass/Ceramic glass/Glass ceramic panel/Induction ceramic glass/Induction glass ceramic

Alias: Induction glass,Ceramic glass,Glass ceramic panel,Induction ceramic glass,Induction glass ceramic,screen print induction glass, high temperature-resistant induction glass,etc

Main Technical Data of Fireplace Glass:

Physical, Chemical,Thermal properties:

Other Glass Types In Purpose:

Processing Workcrafts:

1. Cutting

2. Chamfering

3. Inverted edge

4. Surface precision polishing

5. Drilling

6. Coating

7. Surface printing and sandblasting

8. Hot bending

9).Beveling

Glass ceramics is a kind of material made by crystallization of glass. In manufacturing, it needs to melt a kind of glass first, then add special ingredients, then blow, press, inject and pull it, and finally carry out heat treatment, so as to crystallization. It has a wide range of uses, because of its low expansion coefficient, high temperature resistance, high corrosion resistance, not easy to damage and long service life.

The glass ceramic panel of electromagnetic furnace is a kind of mixture of glass ceramics and glass made by sintering and crystallization of appropriate glass particles. The material is hard, dense and uniform, and there is no pollution in the production process. The product itself has no radioactive pollution. It is a new type of environmental protection green material.

The quality indexes of the glass ceramics panel in electromagnetic furnace (high hardness, corrosion resistance, compression resistance, impact resistance, non water absorption, less dust, no radiation) are better than natural stone plate. Adding different inorganic colorants in the raw materials can produce a variety of colors, uniform tone or colorful products. After polishing, the surface of the plate has the pattern or color grain of imitating natural stone. What is more valuable is its crystal clear and soft luster, and it has glass like crystal clear and bright optical effect under the sun.

Products Name: Induction glass/Ceramic glass/Glass ceramic panel/Induction ceramic glass/Induction glass ceramic

Alias: Induction glass,Ceramic glass,Glass ceramic panel,Induction ceramic glass,Induction glass ceramic,screen print induction glass, high temperature-resistant induction glass,etc

Main Technical Data of Fireplace Glass:

Physical, Chemical,Thermal properties:

Other Glass Types In Purpose:

Processing Workcrafts:

1. Cutting

2. Chamfering

3. Inverted edge

4. Surface precision polishing

5. Drilling

6. Coating

7. Surface printing and sandblasting

8. Hot bending

9).Beveling

10).Arc

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products with "3R" policy. For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.