Description

From prototype to high-volume production Raytek Optics is dedicated to manufacturing custom plano optics to meet your precise specifications. Since 2017, Raytek Optics has built a worldwide reputation in custom optics manufacturing pairing traditional craftsmanship with leading-edge technology. Our 50,000 sq. ft. facility houses the larger collection of cnc cutting machines,cnc milling machine centers, double-sided polishing machines,PIB polishing machine, MRF polishing machines, etc in Shanghai,China.

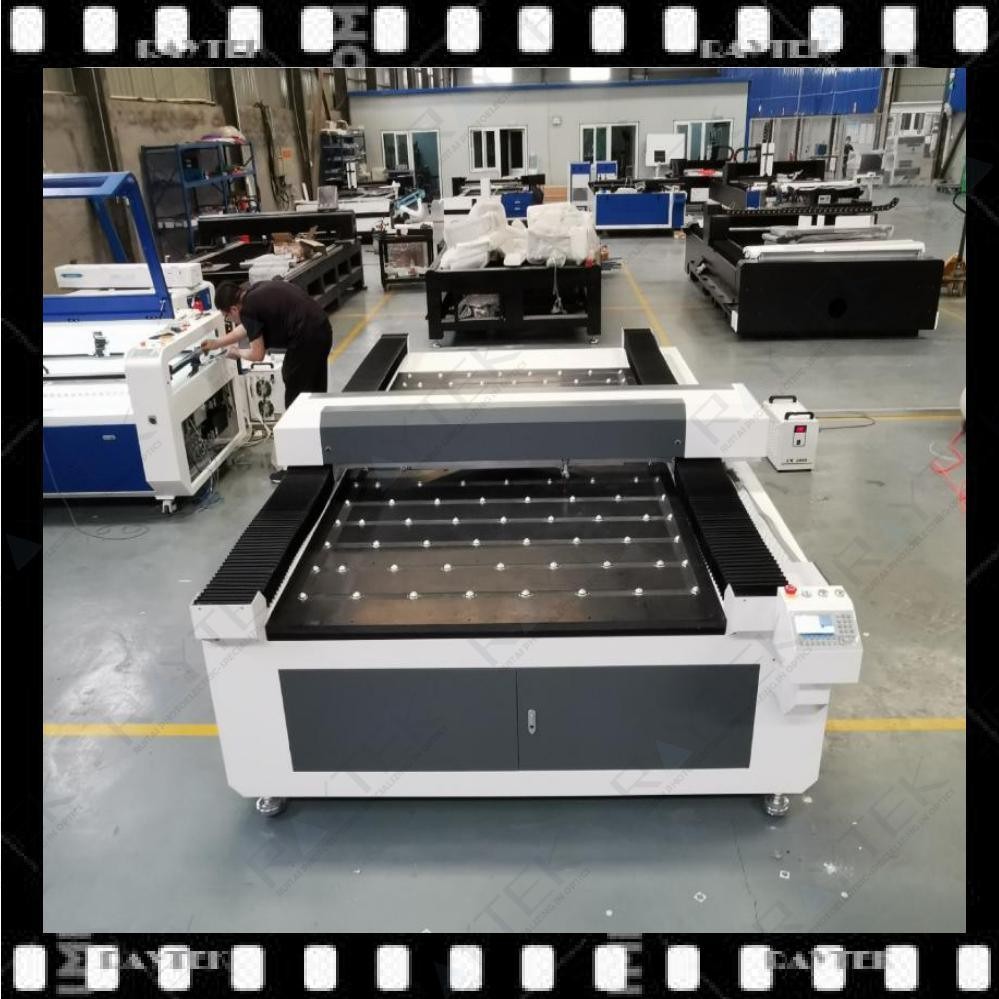

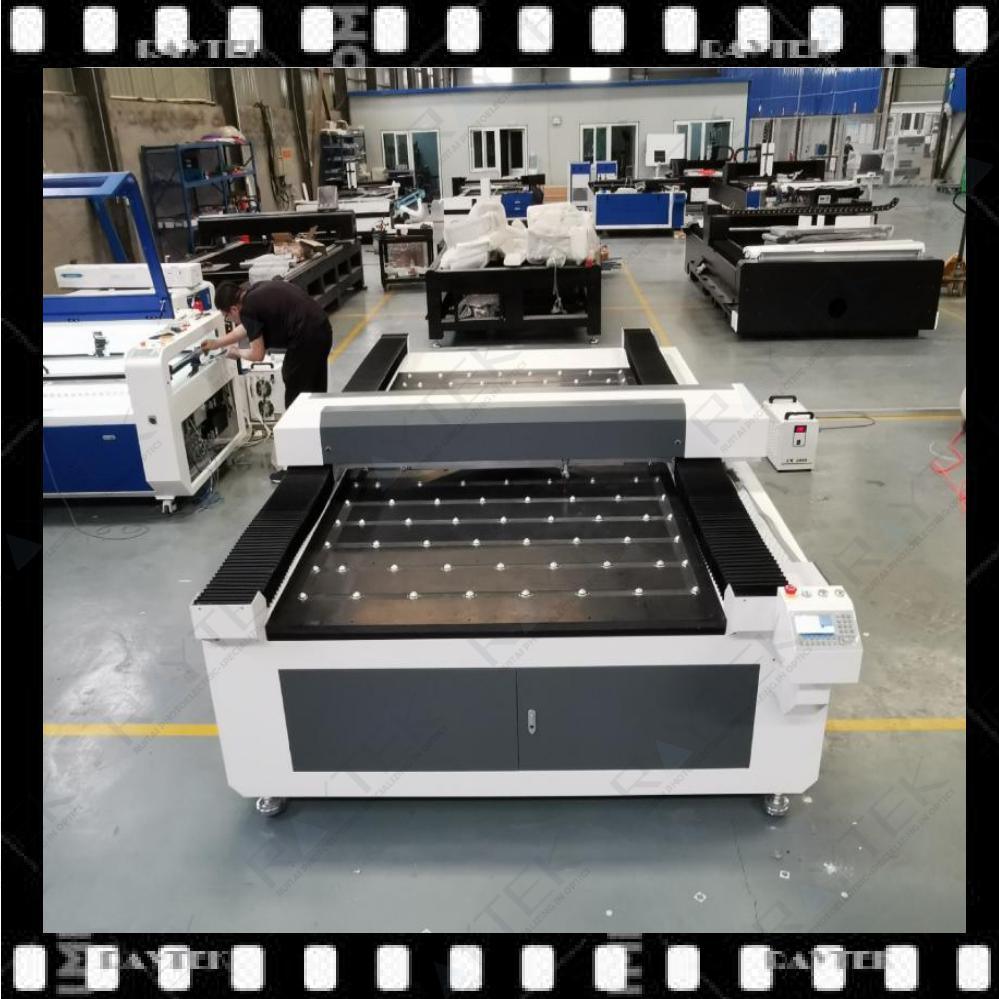

Custom Manufacturing Capacity 3: Laser Cutting/Laser Marking/Laser Engraving

Raytek Optics can offer precision laser cutting for custom shapes, holes, patterns, and more. Custom markings and engravings for serial numbers for tracking, markings for alignment, and more also can be offered. The CNC laser cutting machine of Raytek Optics can laser cut fused silica and fused quartz optical components such as wafers, windows and wedges. Whether you need custom laser cut shapes, patterns or holes, the highly skilled laser technicians at Raytek Optics will meet your tightest tolerances and specifications. Usually laser marking is helpful in identifying, indexing, inventorying and aligning parts. Raytek Optics uses the Epilog Large Format Laser System for laser marking of glass. Laser marking is available on both the surface and edges of circular, square and custom shaped glass parts.

By using state-of-the-art precision laser cutting and marking equipments, guided by highly-skilled experts, Raytek Optics can provide cost-effective solutions for cutting, marking and engraving your optical components both with or without optical coatings. With a custom built beam delivery system, Raytek Optics laser technicians can overcome the challenges of laser cutting substrates with highly reflective coatings. Raytek Optics can even laser cut wafers or other finished optics that contain electronic components and laser mark virtually any type of glass including laser sensitive glass.

Main Processing Technical Capacity Data:

Main Cutting Technologies Advantages:

1).High precision: suitable for cutting precision accessories and fine cutting of various craft characters and paintings;

2).Fast speed: more than 100 times of WEDM;

3).The heat affected zone is small and not easy to deform. The cutting seam is smooth and beautiful without post-processing;

4).Solid state YAG laser is one of the most stable and mature products in laser field;

5).It can complete the processing of various complex structures, as long as it can draw any image on the computer, the machine can complete the processing;

6).YAG cutting machine has automatic tracking system, so it can complete plane cutting and various uneven surface cutting;

7).The cutting surface is very smooth and the product grade is very high; Good cutting quality. Narrow incision width (generally 0.1-0.5mm), high accuracy (generally 0.1-0.4mm hole center distance error, 0.1-0.5mm contour size error), and good surface roughness (generally 12.5-25 RA) μ m) Generally, the cutting seam does not need to be reprocessed;

8).The thickness of glass is 0.1-3 mm, the edge chipping is less than 50 μ m, the cutting edge is bright without burr, and no edge chipping can be achieved by using high-order laser;

8).Clean, safe and pollution-free. It greatly improves the working environment of operators. Of course, in terms of accuracy and surface roughness, CO2 laser cutting can't surpass EDM; In terms of cutting thickness, it is difficult to reach the level of flame and plasma cutting. However, the above remarkable advantages are enough to prove that CO2 laser cutting has replaced some traditional cutting methods, especially the cutting of various non-metallic materials. It is an advanced processing method with rapid development and wide application;

Main Cooperation Materials Manufacturers:

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETC

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Raytekoptics Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products & OEM & ODM service with "3R" policy--return, replace & refund policy.

For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.