Description

Whether the scanning laser system is used for marking, engraving or micro catheter drilling, it depends on the galvanometer to accurately locate the laser beam. Raytek optics uses mirror grade silicon substrate to make galvanometer mirrors that meet the specifications. We used precise thin film coatings on these substrates to produce highly efficient galvanometer mirrors that can reflect wavelengths in the range of 1.0 to 12.0um.

Products Name:

Laser galvanometer/Laser galvanometer mirror/Galvanometer mirror/Galvanometer reflector

Alias:Laser galvanometer,Laser galvanometer mirror,Galvanometer mirror,Galvanometer reflector, Laser galvanometer lens, Galvanometer plate, Laser galvanometer plate,etc

Main Applying:

Laser precision marking, laser rapid prototyping, laser resistance adjustment, laser drilling, laser welding and laser lidars,etc

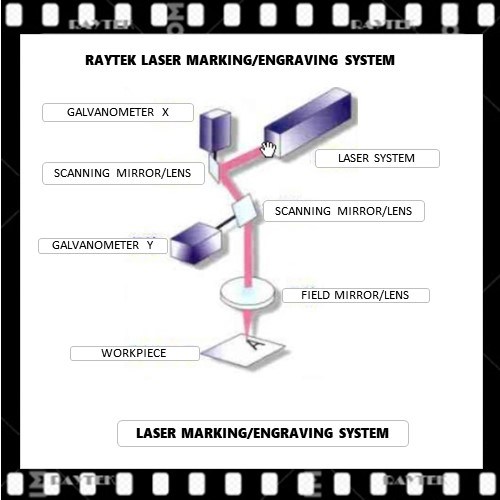

Raytek galvanometer scanning marking head is mainly composed of XY scanning mirror, field mirror, galvanometer and computer-controlled marking software. The corresponding optical components are selected according to the laser wavelength. Related options include laser beam expander, laser, etc. Its working principle is that the laser beam is incident on two mirrors (scanning mirrors) and the reflection angle of the mirrors is controlled by a computer. The two mirrors can scan along the X and Y axes respectively, so as to achieve the deflection of the laser beam and make the laser focus with a certain power density move on the marking material according to the required requirements, thus leaving a permanent mark on the surface of the material, The focused spot can be circular or rectangular, and its principle is shown in the right figure. In the galvanometer scanning system, vector graphics and text can be used. This method uses the graphics software in the computer to process the graphics. It has the characteristics of high drawing efficiency, good graphics accuracy and no distortion. It greatly improves the quality and speed of laser marking. At the same time, the galvanometer marking can also adopt the dot matrix marking method, which is very suitable for online marking. According to the production line of different speeds, one scanning galvanometer or two scanning galvanometers can be used. Compared with the array marking mentioned above, it can mark more dot matrix information and has greater advantages for marking Chinese characters. Galvanometer scanning marking has become a mainstream product because of its wide application range, vector marking and dot matrix marking, adjustable marking range, fast response speed, high marking speed (hundreds of characters per second), high marking quality, good optical path sealing performance, strong adaptability to the environment and other advantages, and is considered to represent the development direction of laser marking in the future, It has broad application prospects.

Main Specification:

Unit:mm Main Cooperation Materials Manufacturers:

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,J-FIBER,ETC

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Raytekoptics Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products with "3R" policy. For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.