Description

From prototype to high-volume production Raytek Optics is dedicated to manufacturing custom plano optics to meet your precise specifications. Since 2017, Raytek Optics has built a worldwide reputation in custom optics manufacturing pairing traditional craftsmanship with leading-edge technology. Our 50,000 sq. ft. facility houses the larger collection of cnc cutting machines,cnc milling machine centers, double-sided polishing machines,PIB polishing machine, MRF polishing machines, etc in Shanghai,China.

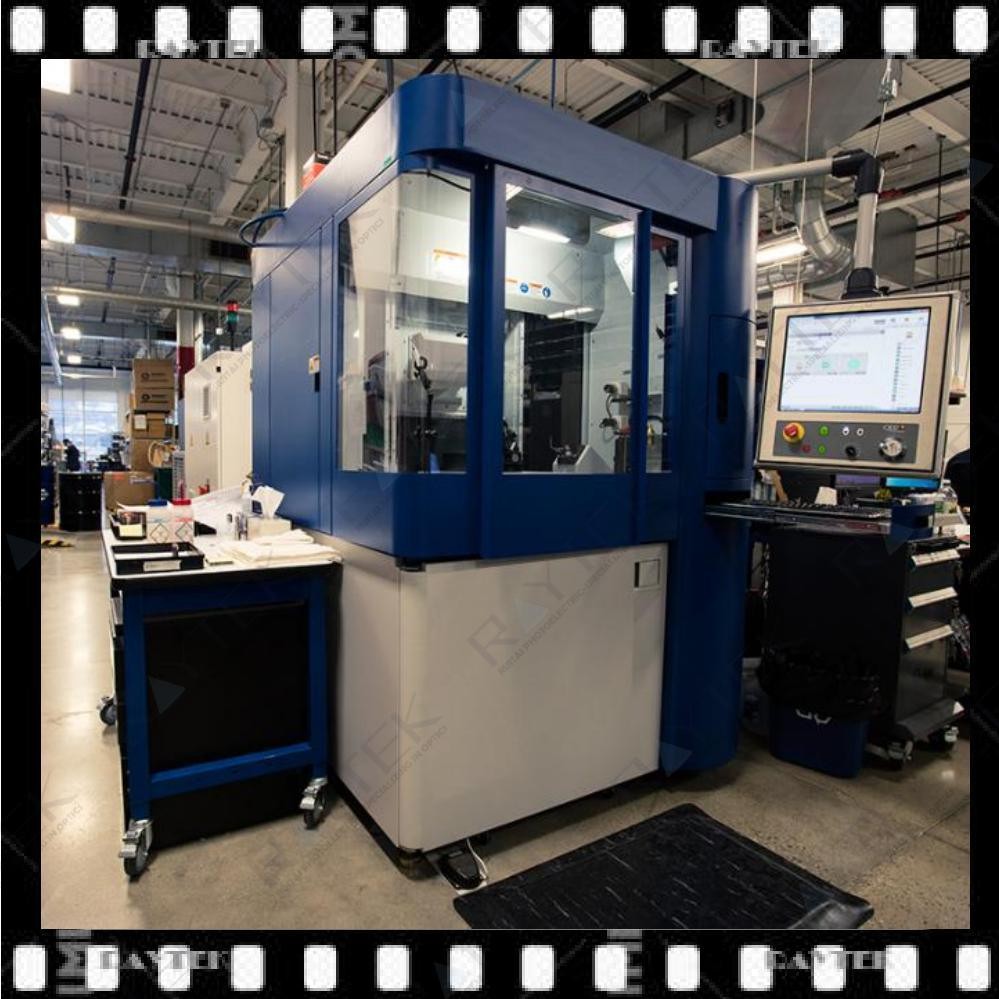

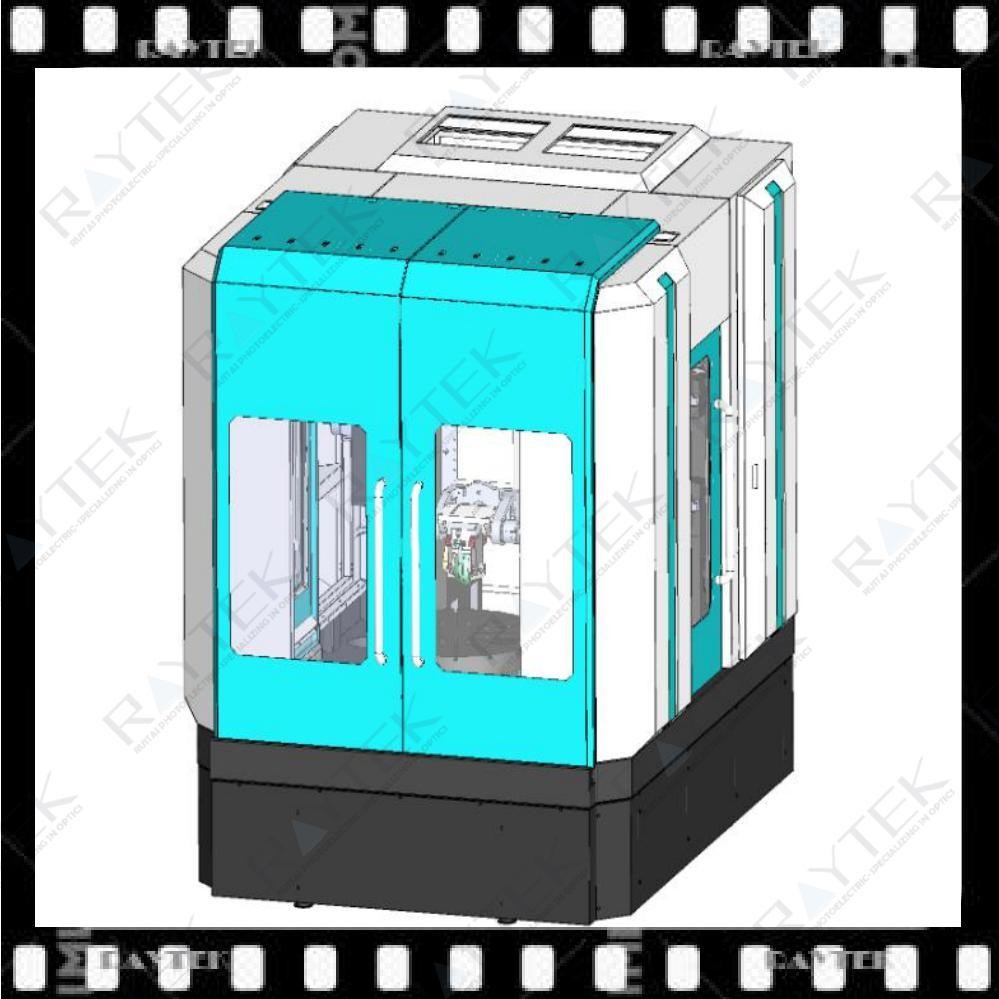

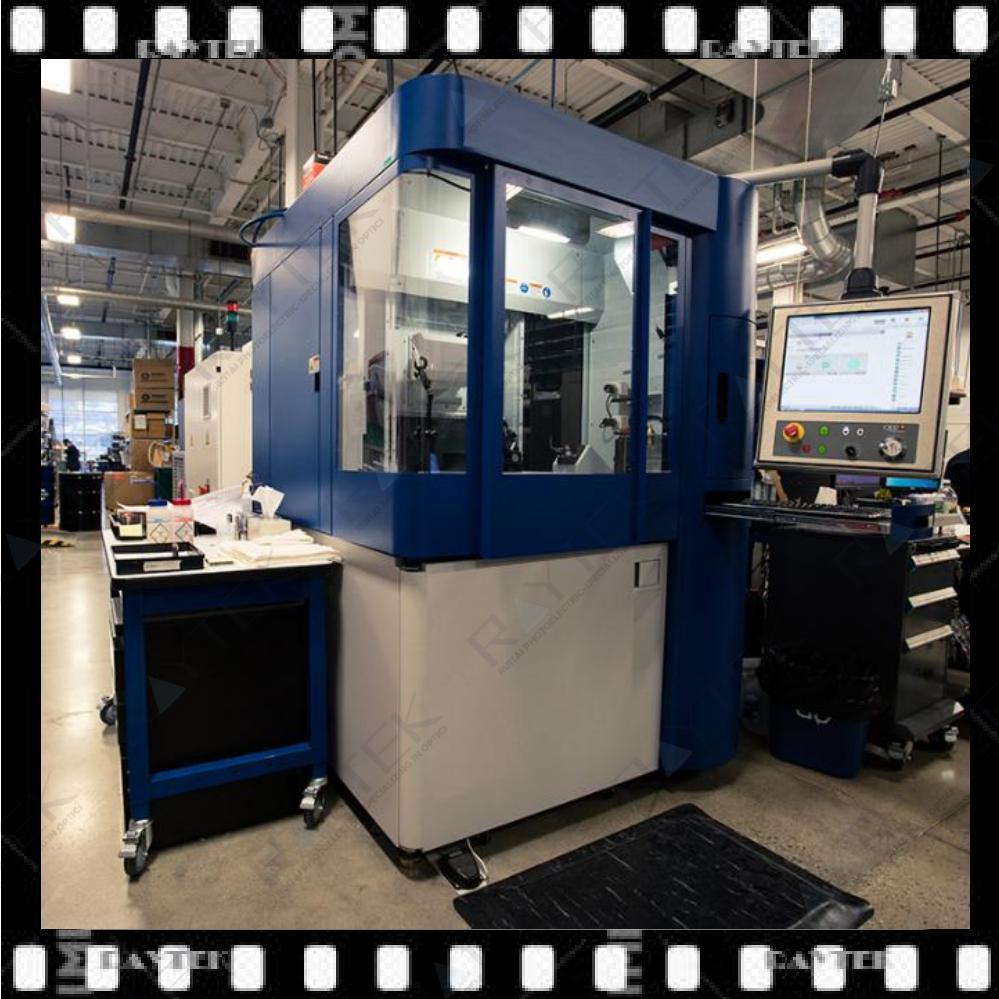

Custom Manufacturing Capacity 7: Magnetorheological Polishing(MRF)

Magnetorheological fluid used in magnetorheological polishing is a kind of intelligent material, which is composed of magnetic particles, base fluid and stabilizer. Under the action of magnetic field, it can realize the reversible conversion of solid-liquid two-phase in 1ms. Magnetorheological effect refers to the phenomenon that magnetorheological fluid is a liquid that can flow without magnetic field, and its rheological properties change sharply under the action of strong magnetic field, which is similar to the properties of solid, and then recover its flow characteristics when the magnetic field is removed. Magnetorheological (MR) polishing technology is a kind of flexible "small grinding head" with viscoplastic behavior, which is formed by the rheology of Mr polishing fluid in gradient magnetic field. It has a rapid relative motion between the grinding head and the workpiece, so that the workpiece surface is subject to a great shear force, and the material on the workpiece surface is removed. Magnetorheological polishing (MRF) is a comprehensive technology which is applied to optical surface processing, such as electromagnetic theory, hydrodynamics, analytical chemistry and so on.

Magnetorheological (MR) polishing machine is used for high-quality and efficient processing of large-diameter optical parts. By combining with the matching process, it can realize the precision polishing and surface shape correction of various shapes and sizes of optical parts within the processing range, achieve the required processing accuracy and surface quality, and improve the processing efficiency.

Main Processing Technical Capacity Data:

Main Cutting Technologies Advantages:

1).No stress;

2).Subsurface damage;

3).High polishing accuracy;

4).The surface roughness is small;

5).Flexible shear has excellent cloud removal characteristics;

6).Bingham fluid is formed by traditional free abrasive polishing under the action of magnetic field, which can realize flexible polishing;

7).Machining and polishing the complicated surface shape, the optical elements are processed determinedly; By controlling various process parameters, it is easy to control the size, shape and strength of the flexible "small grinding head", so as to control the material removal rate. By controlling the motion trajectory and dwell time, various geometric surfaces can be machined (suitable for spherical surface, aspheric surface, free-form surface, etc.)

8).Widely used in optical glass materials such as fused silica, zerodur, soft materials such as Si, CaF2, ZnSe, hard materials such as RB SiC, s-sic, KDP crystal processing, metal mirrors, etc;

9).The polishing spot correction and compensation algorithm can determinedly remove the low frequency error of optical elements and effectively suppress the medium and high frequency error at the same time;

Main Cooperation Materials Manufacturers:

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETC

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Raytekoptics Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products & OEM & ODM service with "3R" policy--return, replace & refund policy.

For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.