Description

General Introduction:

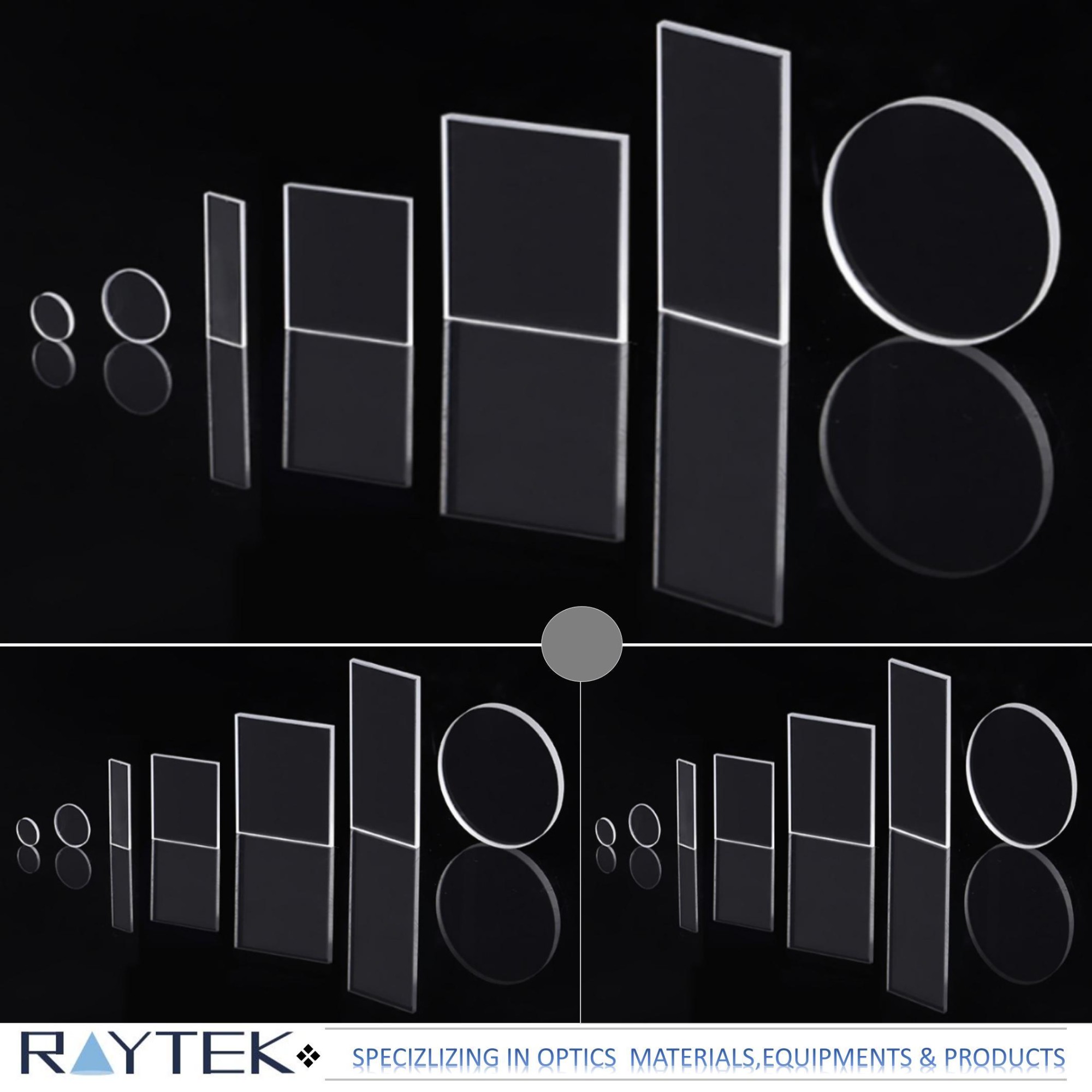

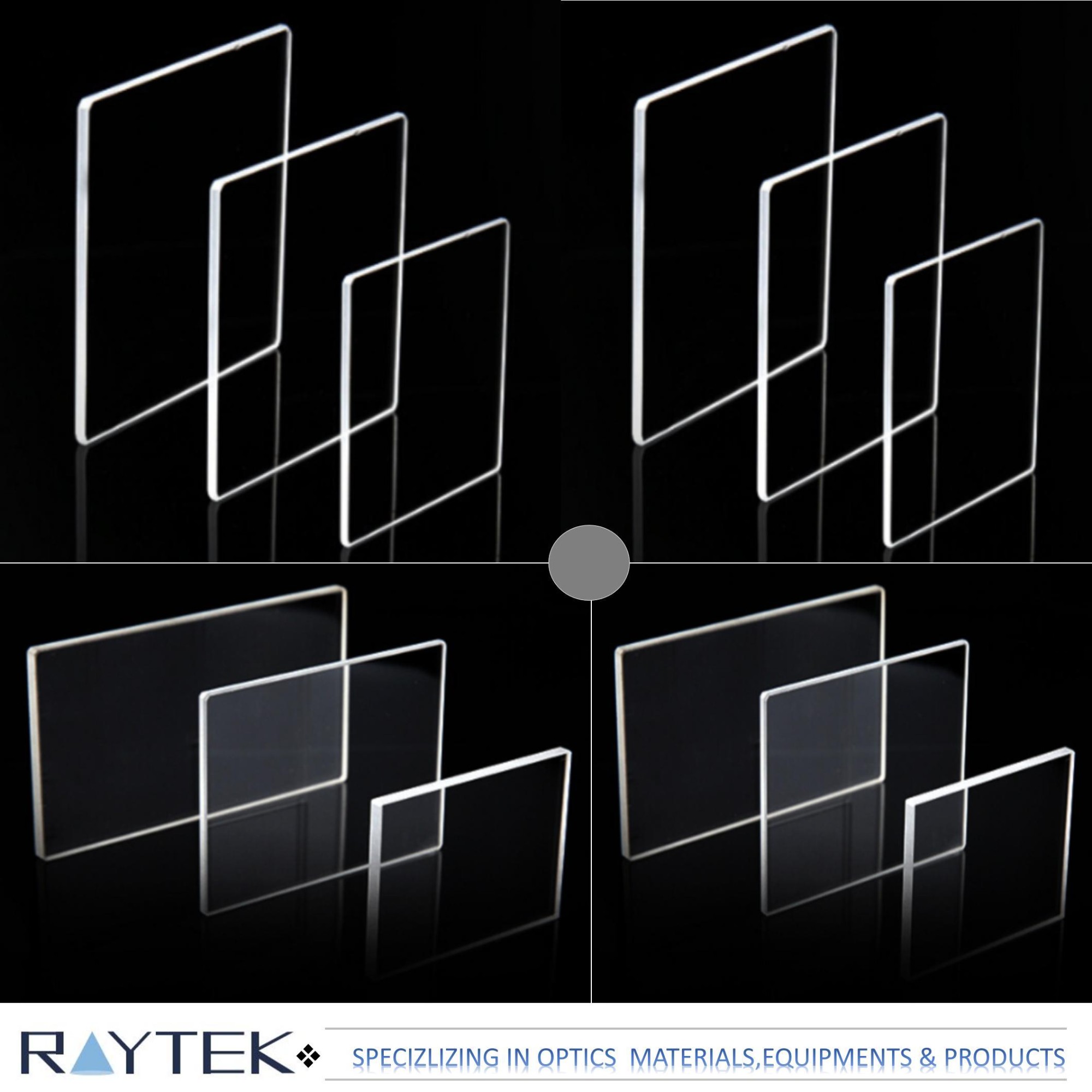

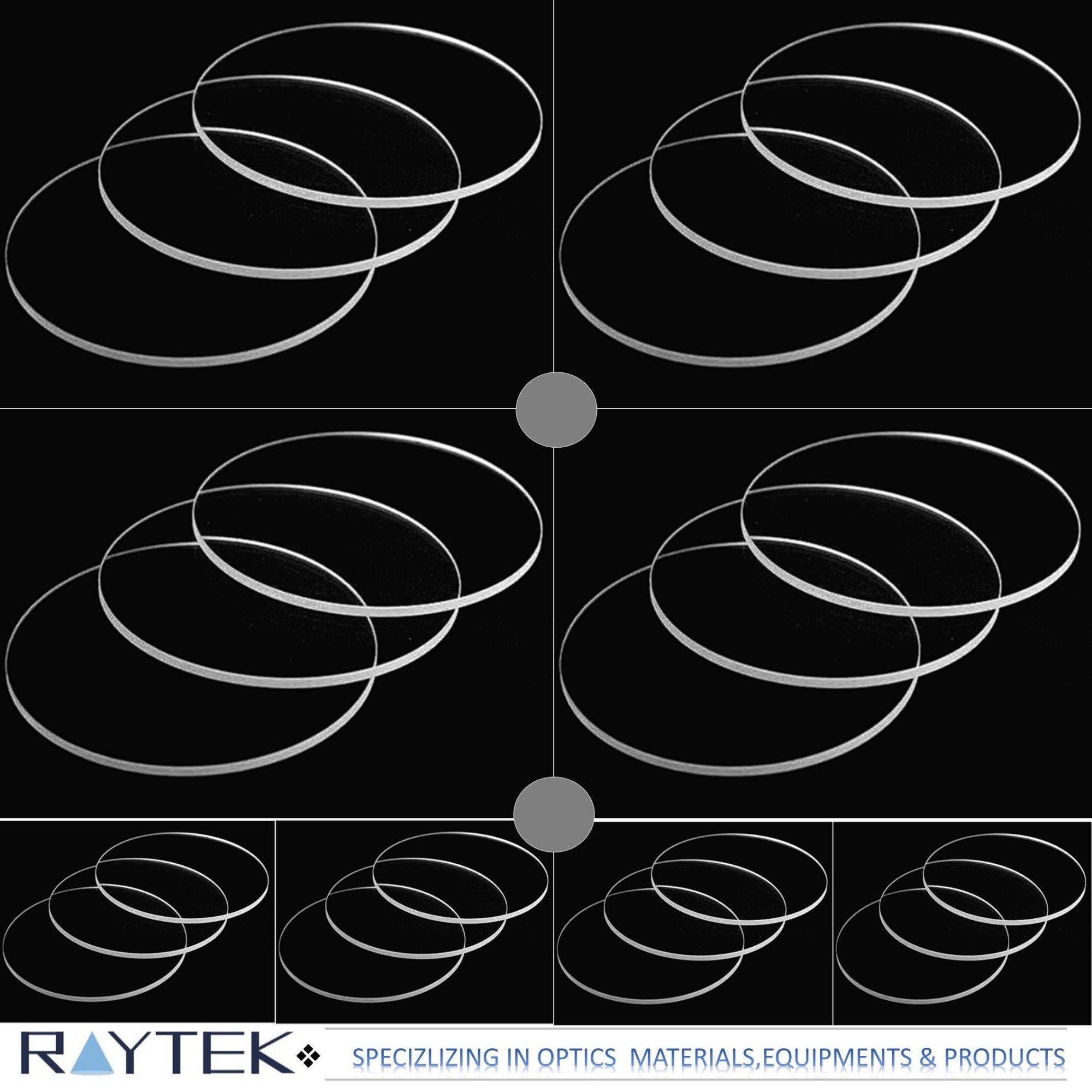

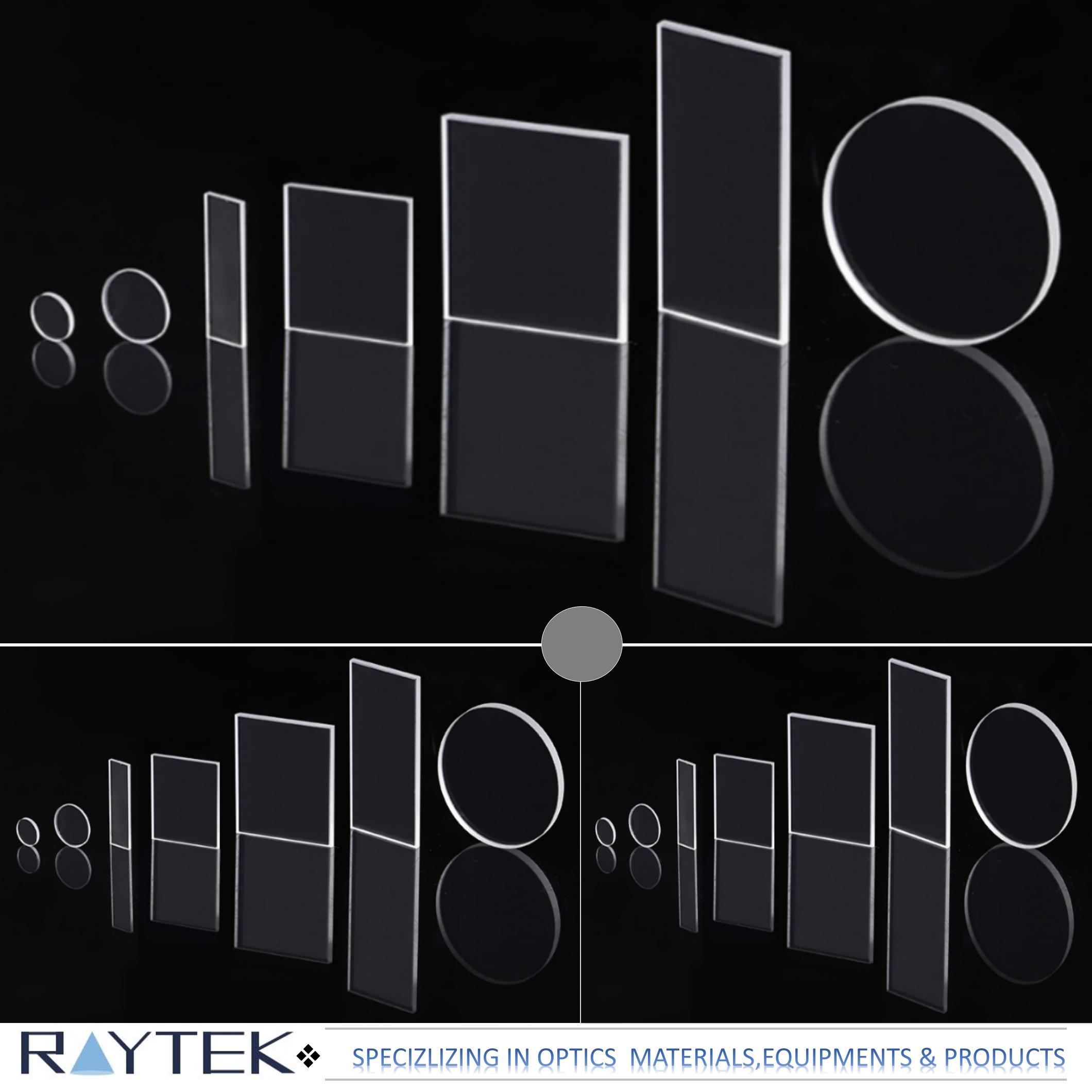

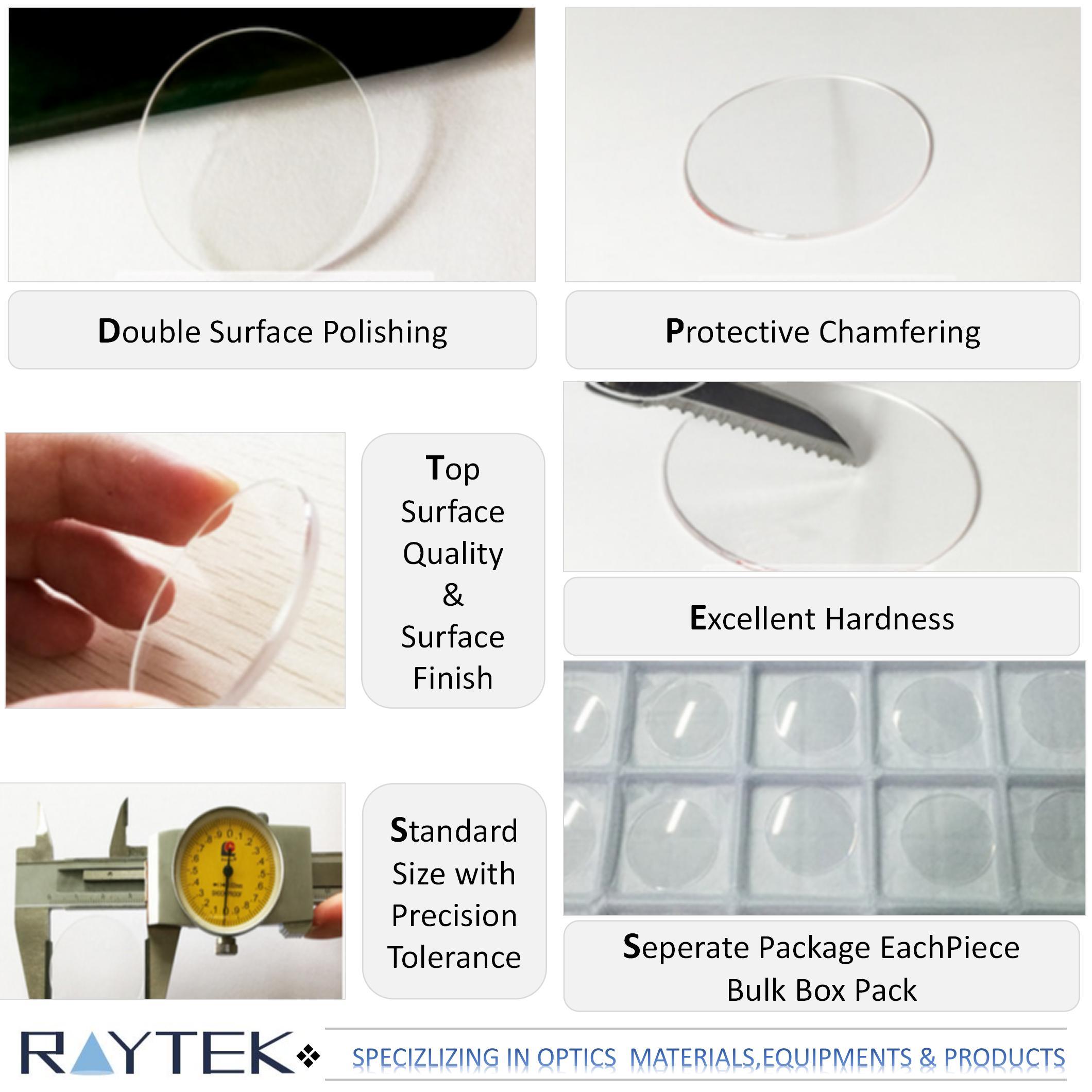

Raytek optical protection sheet, also known as optical protection window sheet and optical window sheet, is an optical plane lens that plays the role of protecting electronic components, sensors and semiconductor components in the optical path. Window slice is one of the basic optical elements in optics. It will not change the optical magnification and only affect the optical path in the optical path. Mechanical properties such as light transmittance, surface accuracy, thickness, parallelism and substrate material are important parameters of window slice.

The optical protective sheet is an optical glass plate with two parallel surfaces formed after fine grinding and polishing. They can be used as protective elements in a variety of complex environments. Their high transmittance makes them have little effect on the passing visible light. The commonly used coatings are anti reflection film (AR) and anti scratch film (as), which can also improve the effect according to the needs of customers. They can be waterproof, dustproof and anti scratch, and can be customized according to the requirements of customers. Optical window film is the pre protection film of optical system. It can be mainly used for the packaging of CCD / CMOS chip, the protection of optical instruments, measuring instruments and digital equipment, various laser equipment, cover film on laser diode, etc.

Basic principle of optical protective film detection

The various impurities in the optical window must be different from the optical window. When light enters the optical window, all kinds of impurities will be different from the surrounding optical window in reflection and refraction. For example, when the uniform light is perpendicular to the optical window, for example, there is no impurity in the optical window, the emission direction will not change, and the detected light is also uniform; When there are impurities in the optical window, the emitted light will change, and the detected image will change accordingly. Due to the existence of impurities, stress concentration and deformation occur around them, and can be easily observed in the image. If light transmission defects (such as cracks, bubbles, etc.) are encountered, the light will be refracted at the defects, and the light intensity is greater than the surrounding, so the light detected on the camera target will be enhanced accordingly; If light absorbing impurities (such as sand) are encountered, the light position at the defect will become weaker, and the light detected on the camera target will be weaker than the surrounding. By analyzing the intensity and image characteristics of the image signal collected by the camera, the corresponding defect information is obtained..

Wide Applying Fields: Experimental Instruments, Aerospace, Semiconductors, Optical instruments, Scientific Research Institutions, Medical Cosmetology, Surveying & Mapping, Intelligent Vehicles, AR/VR,etc

Product Classifications & List:

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Mexico, Brazil, Argentina,Pakistan, India, Portugal, Canada, New Zealand, South Africa, UAE, Egypt, Norway, Netherland, Russia, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optical protective windows products with "3R" policy. For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.