Description

CVD Silicon Carbide is chemical vapor deposited, ultra high purity material used for mirrors or as an optical cladding for UltraSiC material, which is widely used for Optical Applications.

Whether you need one or hundreds of components, Raytek precisely forms, machines, assembles, and tests SiC optical components for a variety of visible and infrared applications in dedicated, quick-turn manufacturing facilities. Raytek high-precision silicon carbide components feature wave front errors and surface roughness equal to or better than traditional substrates. Most typical optical coatings are compatible with our silicon carbide substrates.

Raytek offers expert engineering services including 3D modeling, materials testing, prototyping, and material selection for any optical component specification.

Products Name: Silicon Carbides(SiC)

Alias: Silicon Carbides(SiC), Silicon Carbides,SiC, Sic Optical materials, Silicon Carbides optical materials, CVD silicon carbide, Single phrase silicon carbide, Sic mirrors, Elliptical silicon carbide, Elliptical Sic, Silicon carbide convex, Sic convex, silicon carbide reflector, Sic reflector,etc

Main Characteristics:

1).Low moment of inertia

2).Low dynamic PV

3).High resonance frequency

4).High thermal stability

5).Primary lightweight

6).Quick and convenient mechanical integration

7).Standard and custom design

8).Corrosion resistance and wear resistance

9).Optical polishing modifiable enhancement

Thermal Properties:

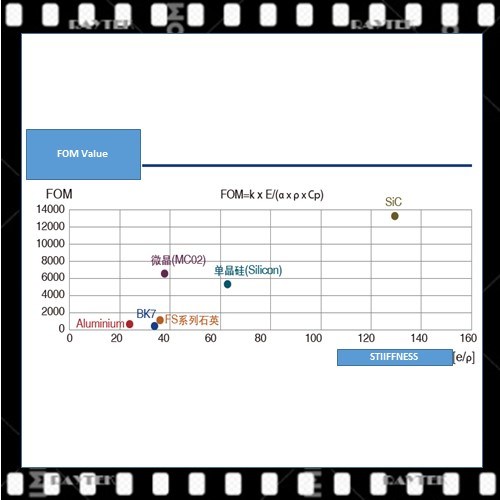

Mechanical Properties:

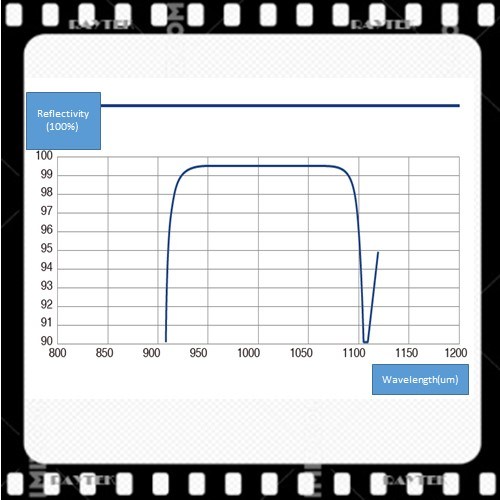

Optical Properties:

Main Applying Fields:

Matching Custom Manufacturing Serivce:

Including Moulding, CNC machining, Polishing, Particle beam processing, Magnetic flux conversion processing, Grinding, Coating, Lightweighting, Custom Shaping, Counterbores, Drilling & Coring, Edge & Bevel Polishing,3D Contouring, Bevels & Chamfers, Steps & Slots, Laser Cutting & Marking, Metrology & Inspection, Precision Pitch Polishing, Double-Sided Polishing, Optical Assembly, Measuring, etc.

Matching processing equipments;

1).Single side lapping and polishing machines

2).Duble sided polishing machines

3).Ring throwing machines

4).DMG five-axis five-linkage spherical milling machine

5).DMG ultrasonic machining center

6).Super large scale gantry cnc machining center (2.0*2.0m)

7).Super large scale surface grinder (1.6m*1.6m)

8).CNC cutting machines

9).Thin plate cleaning machines

10).Ultrasonic trough cleaning machines

11).Plane interferometers

12).Two dimensional detectors

13).Ion beam polishing machines

14).Magnetorheological polishing equipments

Main Cooperation Materials Manufacturers:

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETC

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Raytekoptics Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products with "3R" policy--return, replace & refund policy.

For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.