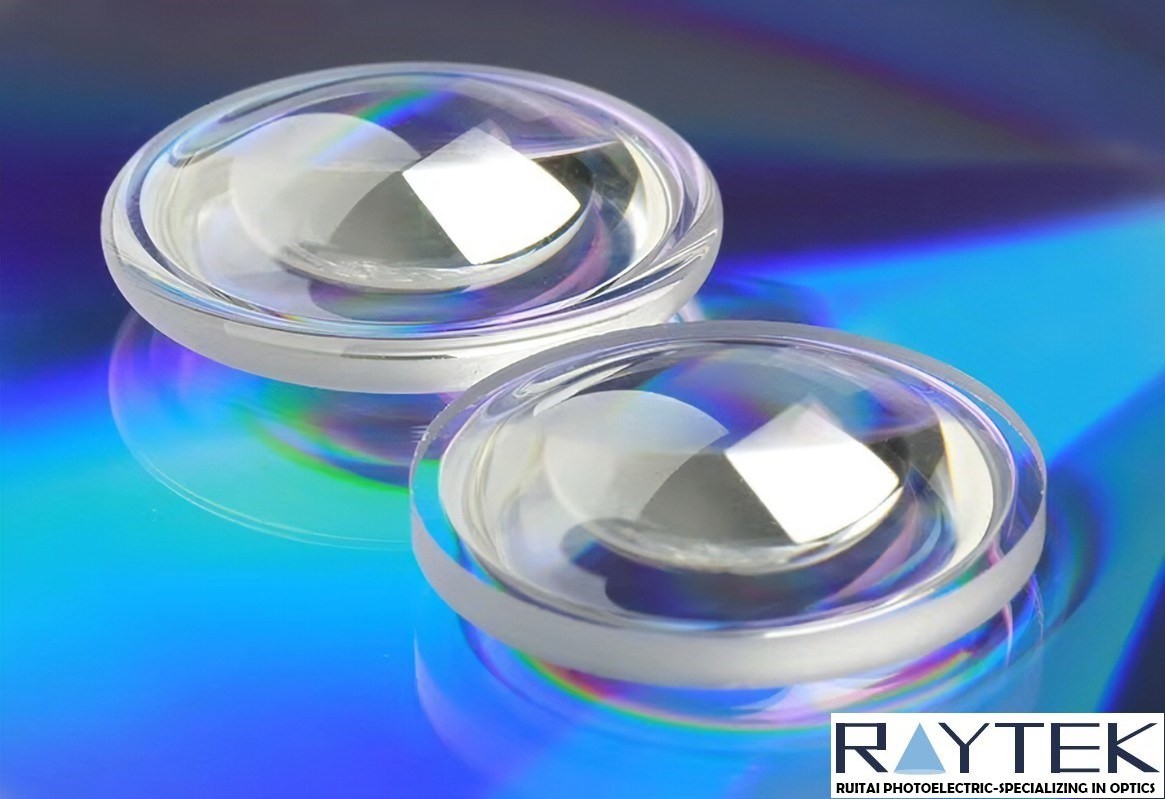

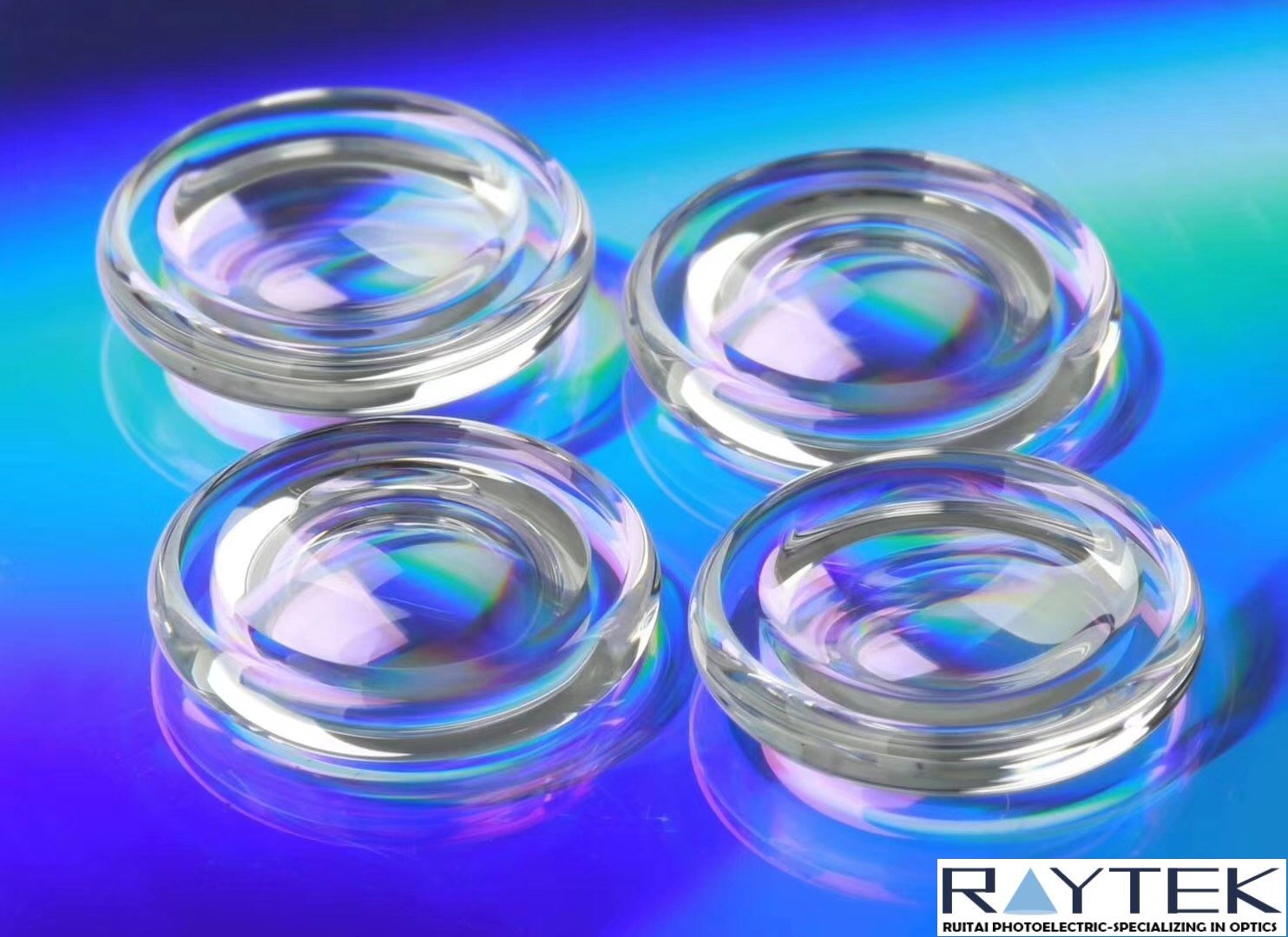

Description

General introduction:Aspheric lenses have better radii of curvature to maintain good aberration correction for the desired performance. The application of aspherical lens brings excellent sharpness and higher resolution, and the miniaturized design of the lens becomes possible.

Product Description:Aspherical lens, the radius of curvature varies with the central axis, to improve optical quality, reduce optical components, and reduce design costs. Compared with spherical lenses, aspheric lenses have unique advantages, so they have been widely used in optical instruments, images, and optoelectronics industries, such as digital cameras, CD players, and high-end microscopy instruments.

Product Features:

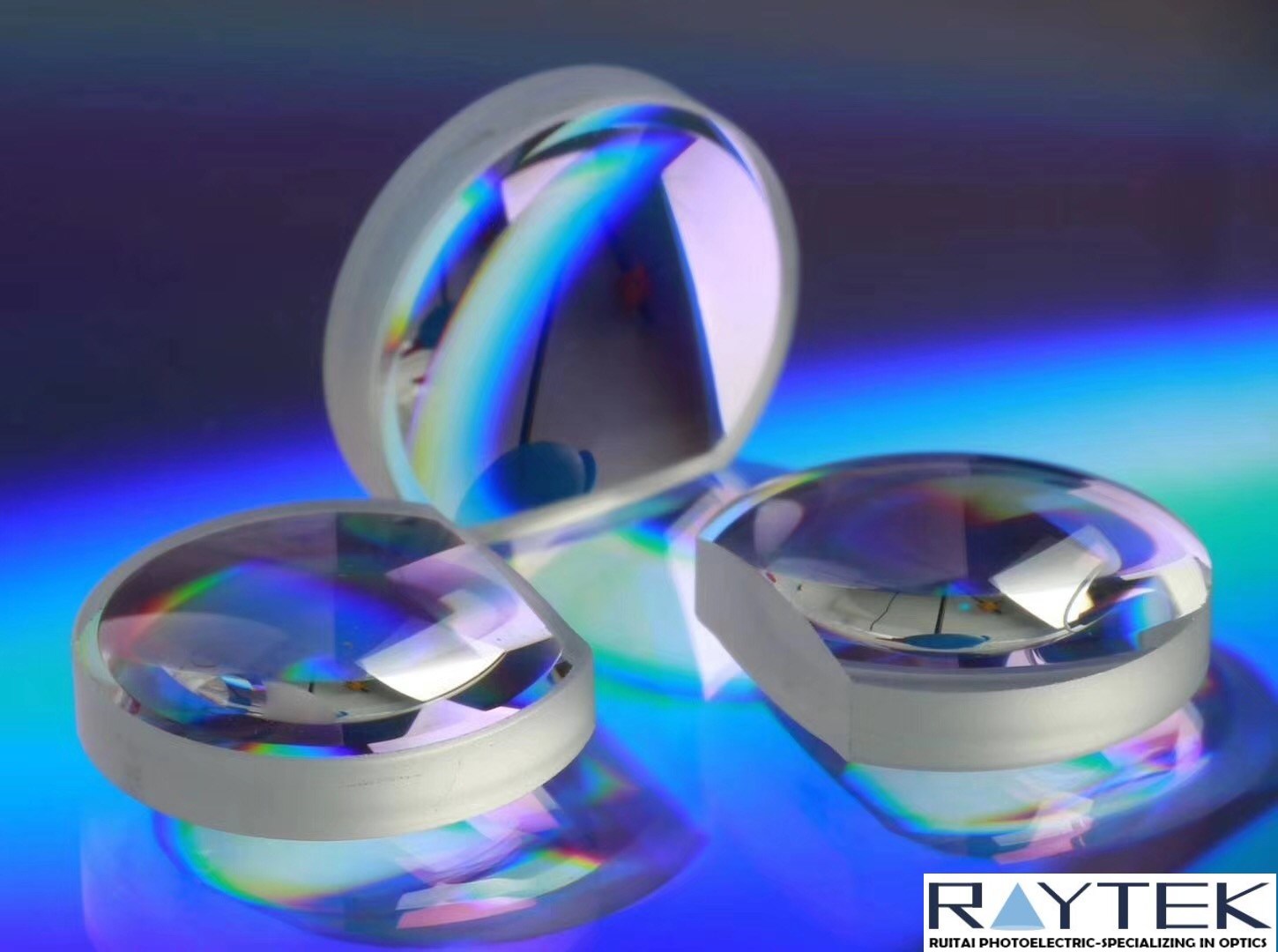

1) Spherical aberration calibration:

The aspheric lens is used to replace the spherical lens, and the most significant advantage is that it can correct the spherical aberration caused by the spherical lens in the collimation and focusing system. By adjusting the surface constant and aspheric coefficient, the aspheric lens can eliminate the spherical aberration to the greatest extent. Aspheric lenses (light converging to the same point) essentially eliminates spherical aberration (light converging to different points, resulting in blurry images) produced by spherical lenses.

2) System advantages:

Aspheric lenses simplify the elements involved for optical engineers to improve optical quality, while increasing the stability of the system. For example, in a zoom system, 10 or more lenses are usually used, but 1 or 2 aspherical lenses can achieve similar or better optical quality, thereby reducing system size, increasing cost, reducing The overall cost of the system.

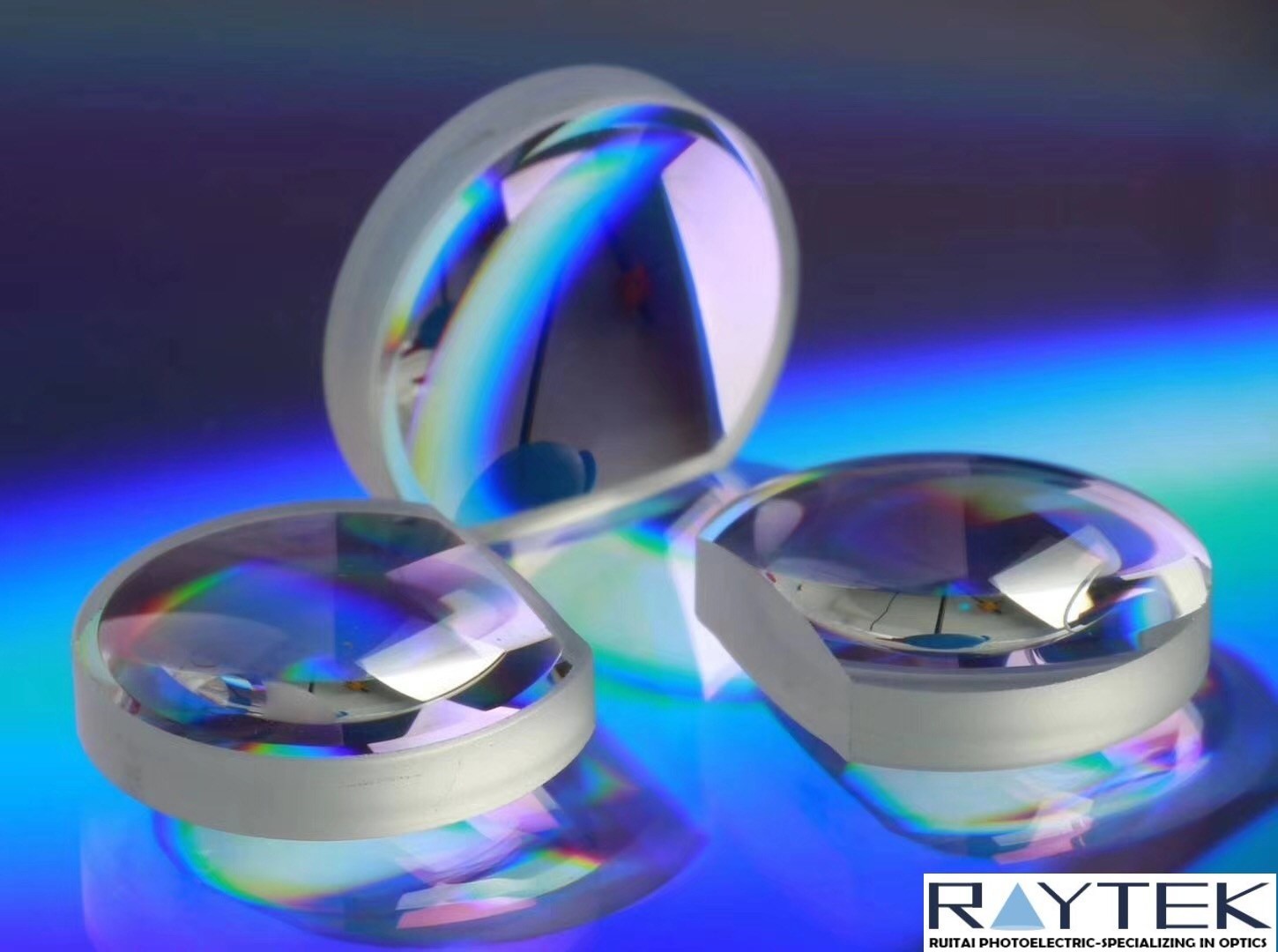

Product type:

a) Precision glass forming aspheric lens, with the characteristics of mass production and high thermal stability, suitable for occasions with large batches, high quality and high thermal stability.

b) Precisely polished and molded aspherical lenses have the characteristics of short sample preparation cycle and no need for molds, which are suitable for sample production and small batches of samples.

c) Hybrid aspheric lens, with the feature of simultaneous calibration of spherical aberration and chromatic aberration, suitable for occasions with wide spectrum, large batch and high quality.

d) Plastic molded aspherical lenses have the characteristics of low cost and light weight, and are suitable for occasions with large batches, moderate quality and low thermal stability.

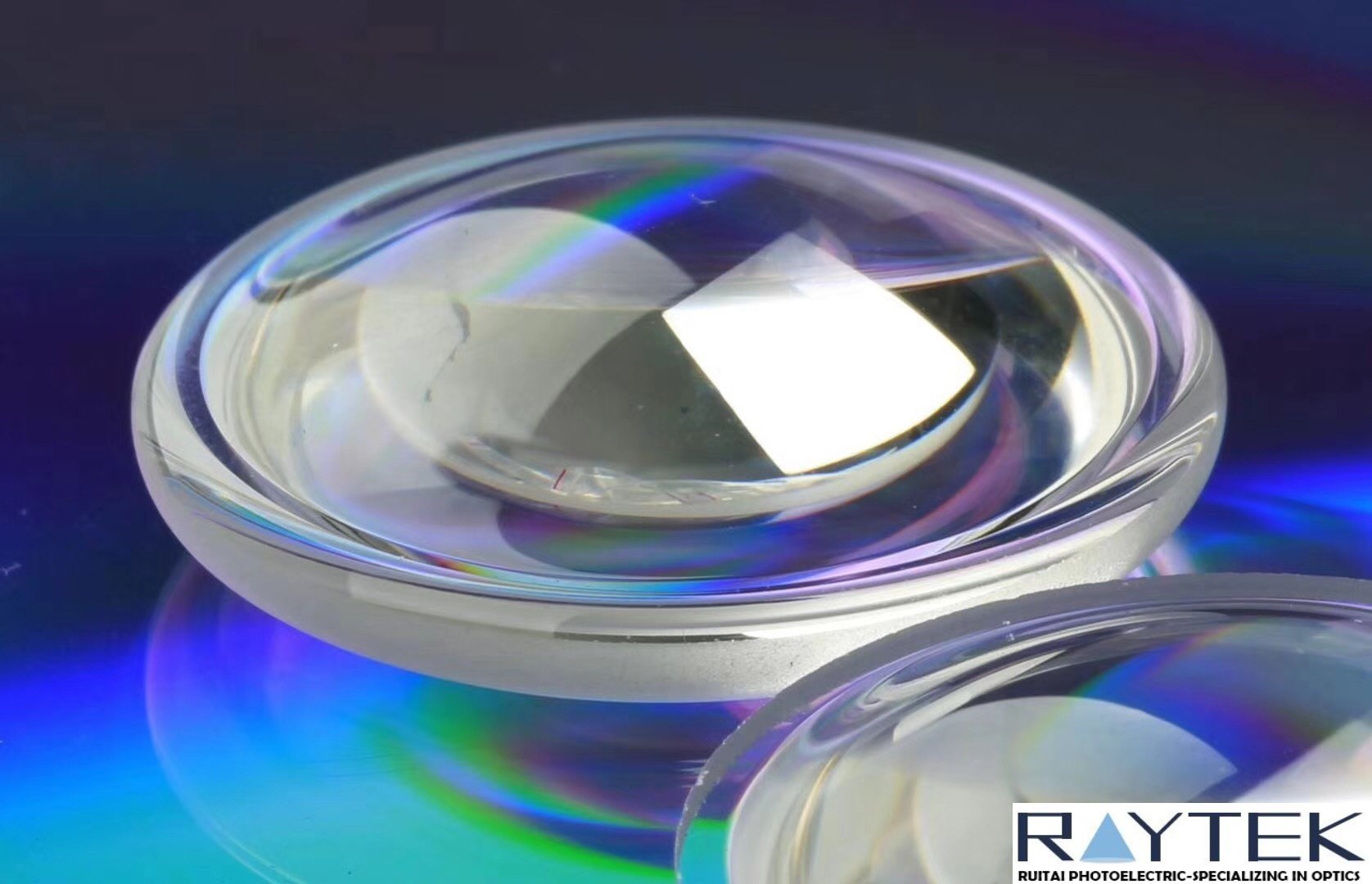

The difference between aspheric lens and spherical lens:

1. Spherical lens, the shape of the sphere corresponds to the section of the sphere, and the sphere is a rotationally symmetric optical element, and the distance between its radius of curvature and the geometric center is constant. This means that the optically effective area can be described by specifying only one parameter, the radius R. Since this parameter is constant over the entire surface, the sphere has a relatively economical cost advantage in manufacturing.

2. If other factors are considered in the optical setup, such as high image quality, numerical aperture or space saving, aspheric lenses are the best choice. Aspheric lenses are rotationally symmetric optical elements with a radius of curvature that deviates radially from the center of the lens. Due to this special surface geometry, the difference between aspheric lenses and spherical lenses, aspheric lenses can significantly improve the imaging quality of the optical system. Their different radii of curvature lead to deviations from spherical lenses.

In terms of imaging quality, aspherics clearly dominate, but the difference between aspherical and spherical lenses is still reflected in higher production/measurement requirements and higher process costs. The table below shows a basic comparison of the two lenses:

Main Cooperation Materials Manufacturers:

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETC

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Raytekoptics Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products with "3R" policy. For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.