Description

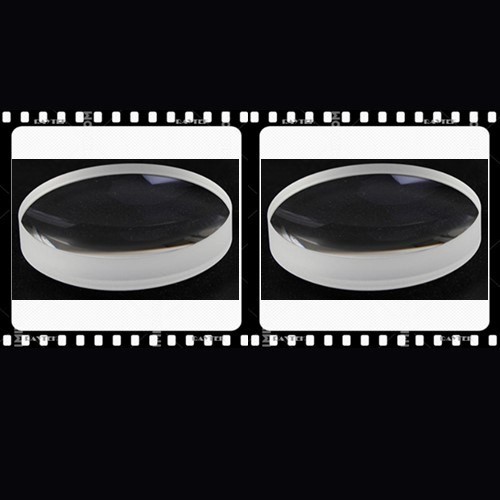

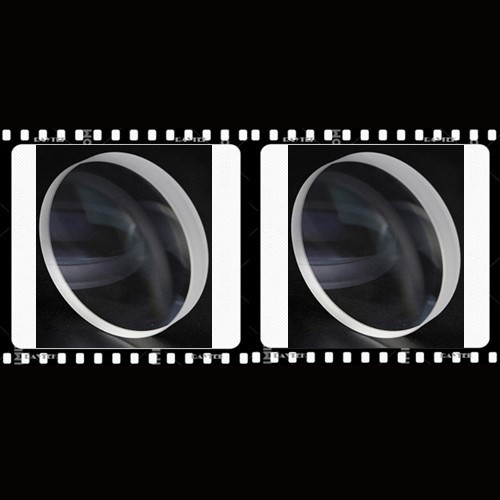

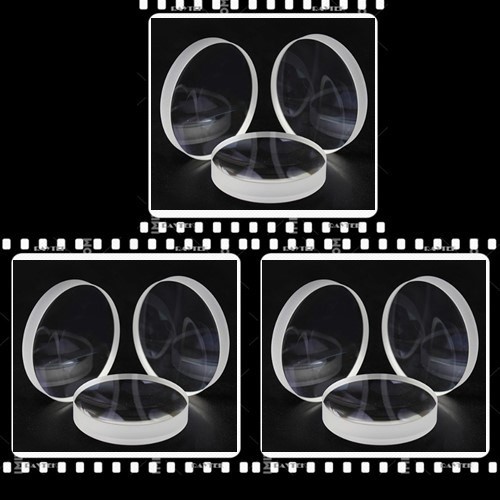

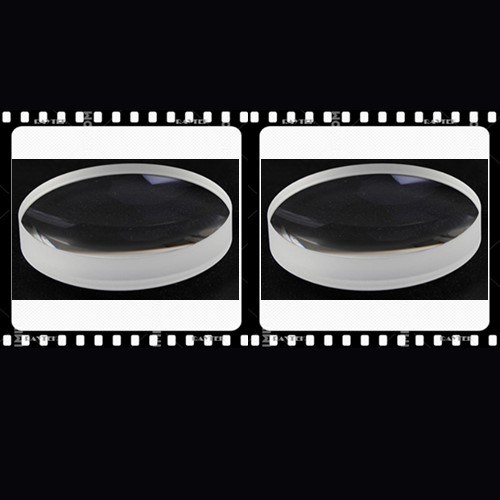

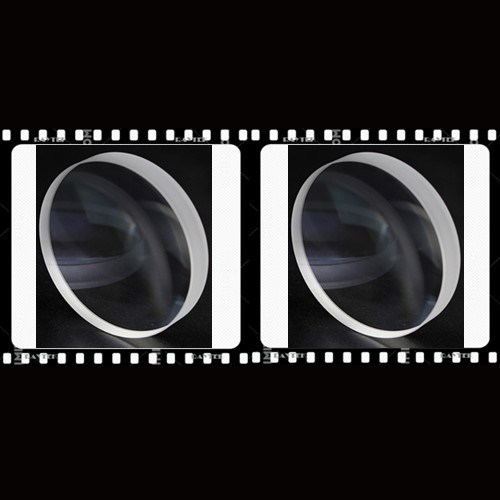

Products Name: Uncoated UV Fused Silica Plano-Convex Lenses

Alias: Uncoated UV Fused Silica Plano-Convex Lenses,Uncoated UV fused silica plano-convex lens, Uncoated fused silica plano-convex lens, Uncoated fused silica lens,etc.

Lens Substrates:

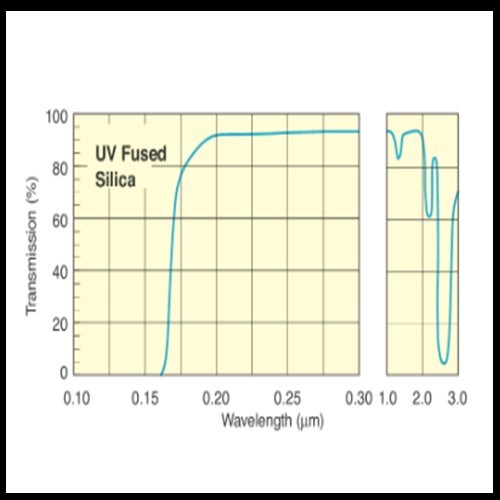

UV fused silica substrate for UV region, laser line and wide band applications

UV fused silica is a synthetic amorphous silica with high purity, which can provide the maximum transmission from 195 nm to 2100 nm. The amorphous and colorless quartz glass has very low thermal expansion coefficient, good optical properties and excellent transmittance in the ultraviolet region. The transmittance and uniformity are higher than that of crystal quartz, and there is no inherent orientation and temperature instability of crystal form. It does not fluoresce under ultraviolet light and is radiation resistant. For high energy applications, the high purity of fused silica eliminates the micro defects that may cause laser damage. For more information, please refer to the summary of optical materials technology.es

Advantages of uncoated lens

Uncoated lenses are used in optical systems and equipment, mainly because they have a very wide wavelength range, high damage threshold ratio, and do not need to be coated, so they are always cheaper than coated lenses. In addition, the uncoated lens makes the image in the camera look more "retro", which is becoming more and more popular in cinema film production.

Main Applying:

Products Highlights:

1).Uncoated planoconvex lens for focusing

2).UV grade fused silica substrate

3).Surface irregularity<=λ/8, scratch less than 0.02mm, pitting less than 0.01mm

4).Standard focal length suitable for various lens sizes

5).Different grades materials for option.

6).High precision & high surface roughness;

7).Sizes can be customized as per the customers' request

8).Quick lead time and delivery time.

9).Matching super optics custom and processing capacity, including Moulding, CNC machining, Polishing, Particle beam processing, Magnetic flux conversion processing, Grinding, Coating, Lightweighting, Custom Shaping, Counterbores, Drilling & Coring, Edge & Bevel Polishing,3D Contouring, Bevels & Chamfers, Steps & Slots, Laser Cutting & Marking, Metrology & Inspection, Precision Pitch Polishing, Double-Sided Polishing, Optical Assembly, Measuring, etc.

10).Excellent post-sale quality warranty, with "3R"-return, replace & refund policy

Main Optical Tech Specification:

Main Physical Size Specification:

Other Available Lens Substrates:

UV fused quartz,Molded glass,Fused silicon glass,N-BK7,K9,K7,B270,D-LAK,D-ZK3,D-ZLaF52LA18

D-ZLaF52La9,ECO5508,L-BAL 35 (589/611)48,7980/7979/7972/7973/SQ0/1/8655/SK1300/1310

NIFS/BK7/N-SF6/N-SSK/SBL7/Zerodur/CaF2/SIC,et

Main Cooperation Materials Manufacturers:

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETC

Main Export Countries & Areas: Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Raytekoptics Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products with "3R" policy. For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.