Description

From prototype to high-volume production Raytek Optics is dedicated to manufacturing custom plano optics to meet your precise specifications. Since 2017, Raytek Optics has built a worldwide reputation in custom optics manufacturing pairing traditional craftsmanship with leading-edge technology. Our 50,000 sq. ft. facility houses the larger collection of cnc cutting machines,cnc milling machine centers, double-sided polishing machines,PIB polishing machine, MRF polishing machines, etc in Shanghai,China.

Custom Manufacturing Capacity 4:

3-axis/4-axis/5-axis CNC Milling & Cutting, CNC Milling & Engraving, CNC Milling & Drilling

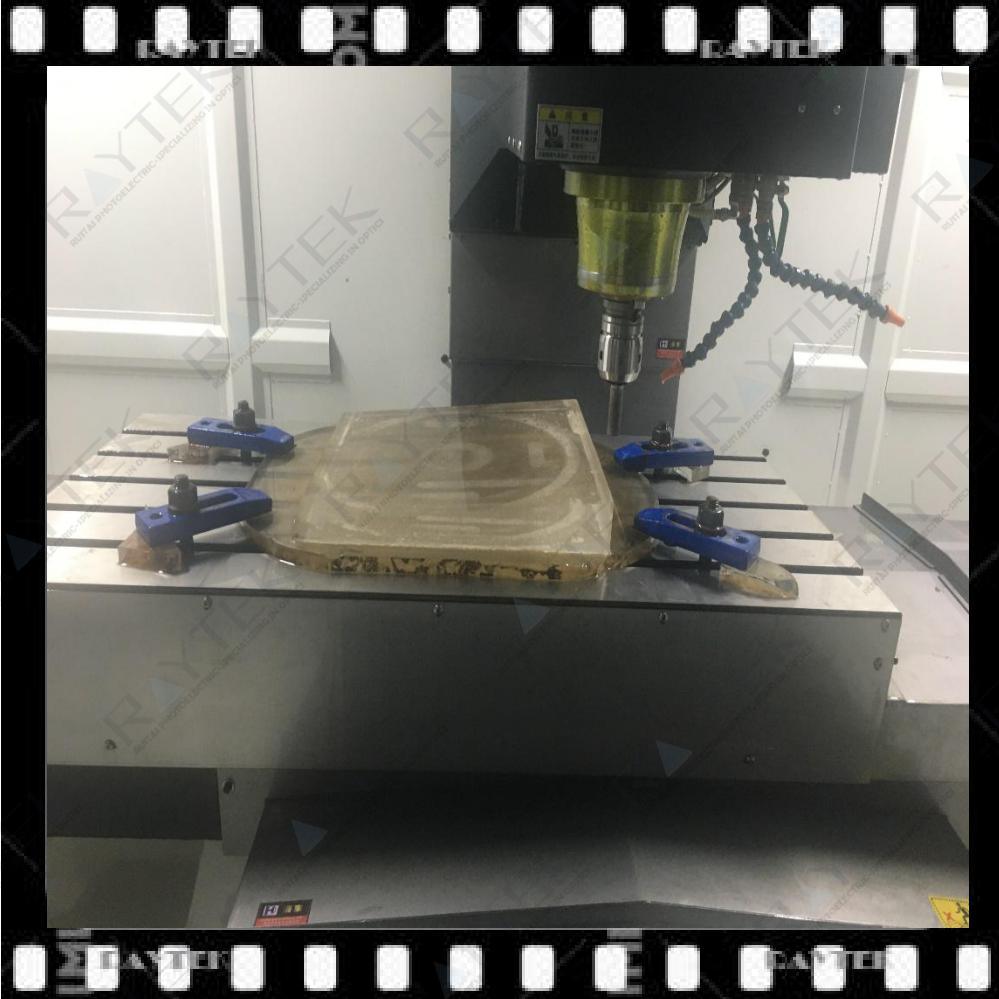

Aspherical Lightweighting & Spherical Lightweighting/Optical lens Lightweighting

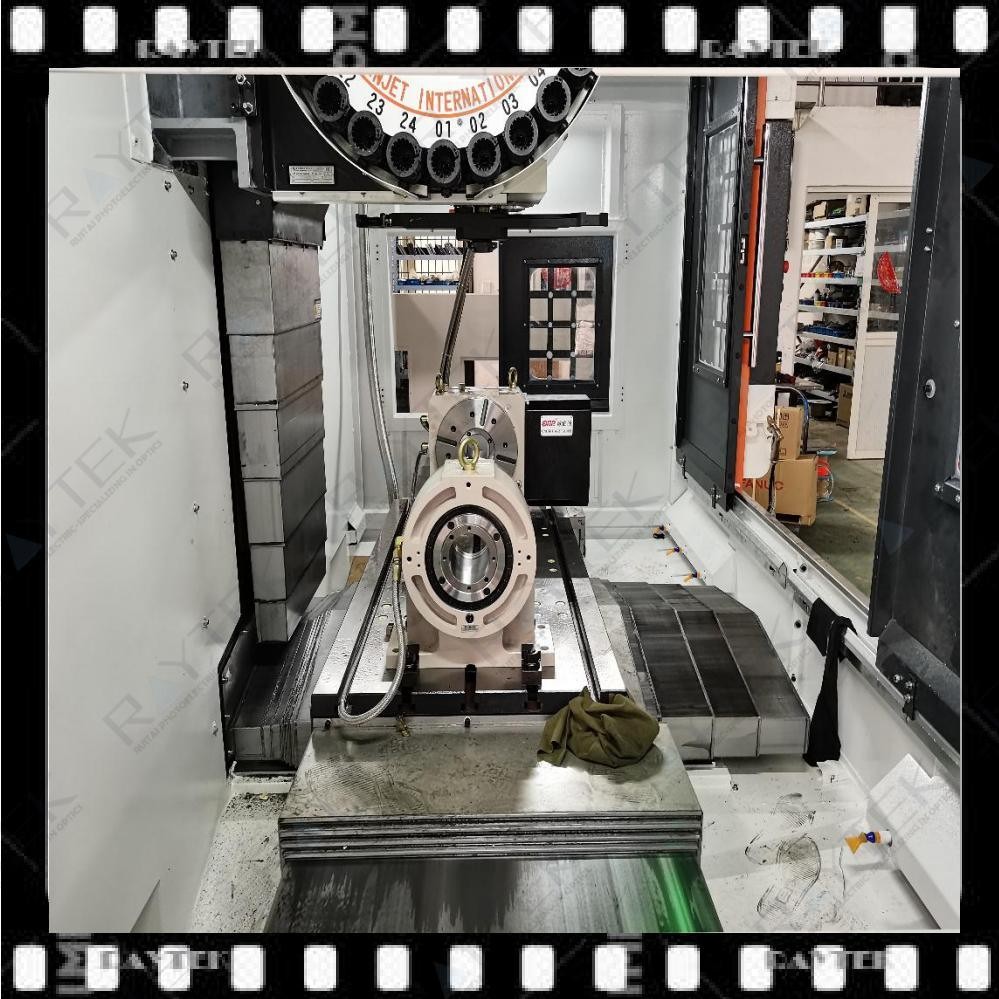

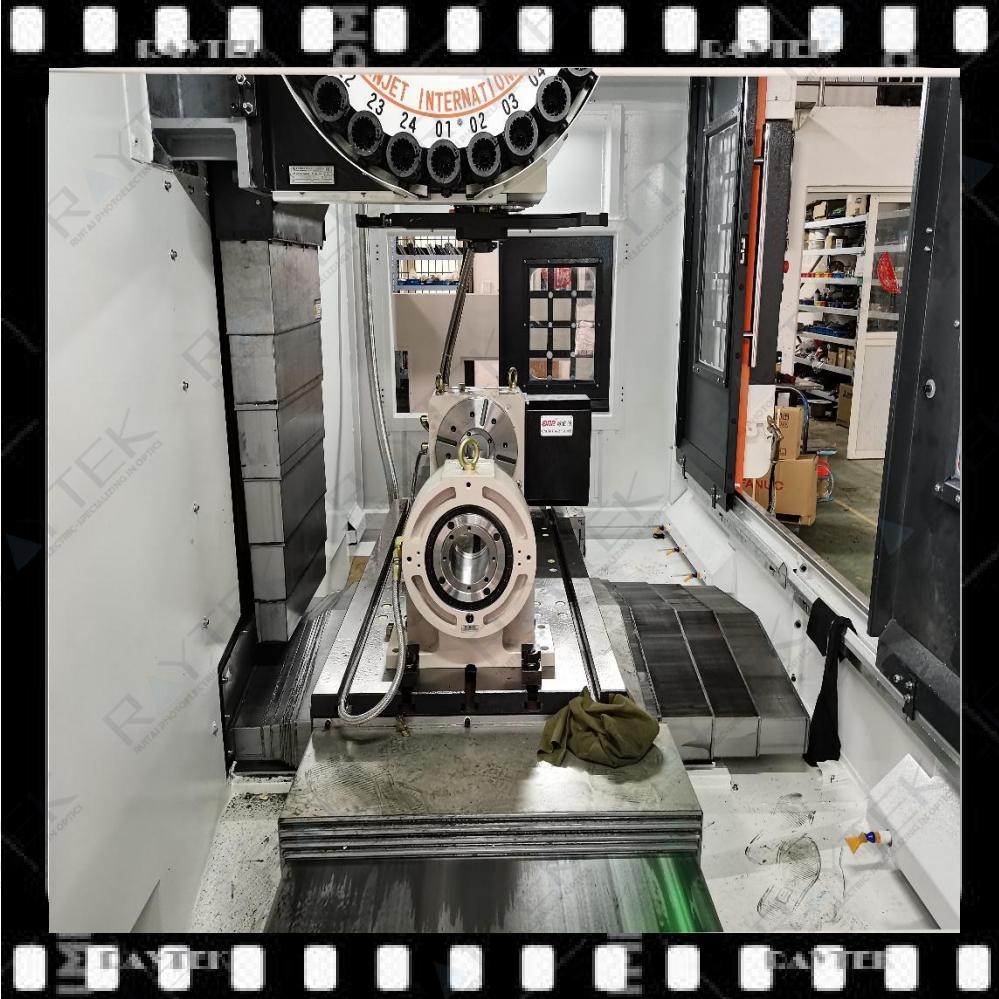

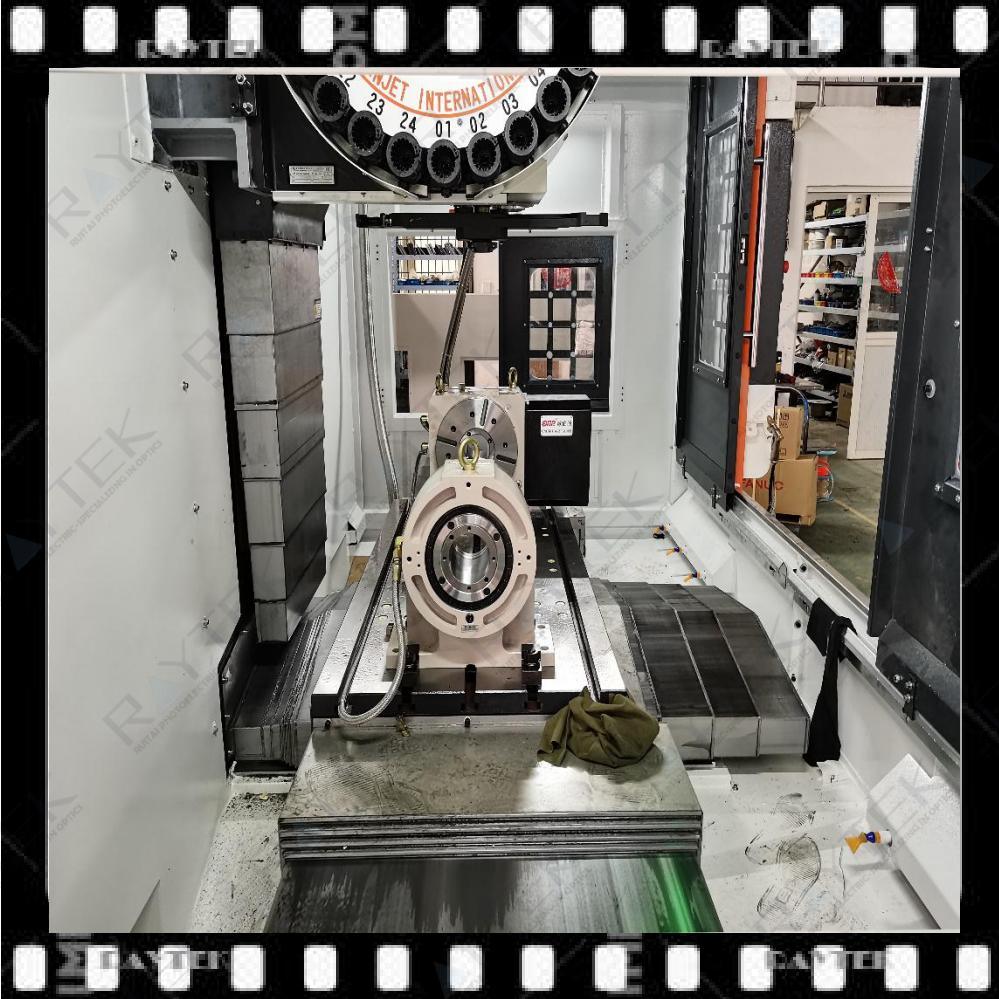

When it comes to fabricating custom optical components, Raytek Optics uses state-of-the-art CNC machines and leading experts to handle even the most intricate optical designs, specifications, and demands.Raytek Optics has a vast array of CNC glass machining equipment, including the Yongshuo YSV-1160, YS-2019 and Yongshuo YSWZ-650, Cradle type 5-axis CNC machining centers with SIEMENS 840DSL, Yongshuo YSD-1280, YSD-1520 CNC Milling & Engraving Machine Centers with a FANUC robotic arm to automate large production volume projects. Regardless of the machine used, every job adheres to the same quality standards to meet your glass CNC machining needs and precise specifications.

Raytek Optics can machine your lightweight design pattern to achieve optimal performance for your finished product, including lightweighted glass, which requires superior craftsmanship to maintain the structural integrity of glass optics while reducing overall weight.

With the aid of the latest CAD / CAM software systems combined with cutting-edge equipment and expert CNC machine operators, Raytek Optics has the ability to manufacture the most complex geometries and tightest tolerances by cnc machining.

Main Processing Technical Capacity Data:

Main Cutting Technologies Advantages:

1).It has high machining precision and high machining quality

2).It can carry out multi coordinate linkage, and can process complex parts;

3).When the shape and size of parts need to be changed, just change the NC program to save production preparation time

4).The machine tool itself has high precision and high rigidity. It can set appropriate processing capacity and improve processing efficiency

5).The machine tool has a high degree of automation, which reduces the labor intensity of workers

6).Mass production, product quality easy to control;

Main Cooperation Materials Manufacturers:

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETC

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Raytekoptics Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products & OEM & ODM service with "3R" policy--return, replace & refund policy.

For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.