Description

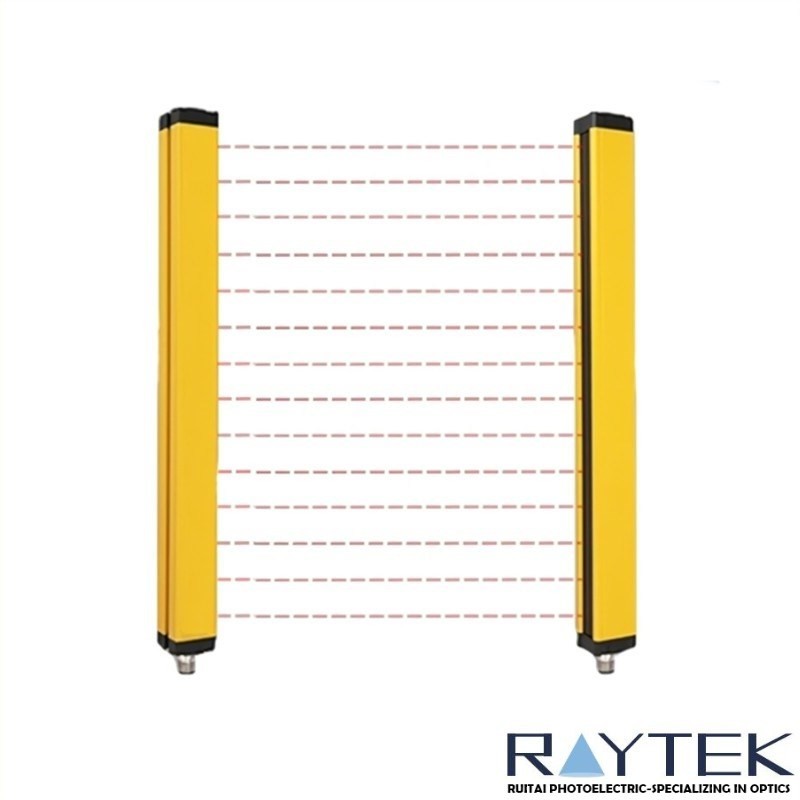

An optical device composed of a large number of parallel slits of equal width and spacing is called a grating. The commonly used grating is made by engraving a large number of parallel notches on the glass sheet. The notches are opaque parts, and the smooth part between the two notches can transmit light, which is equivalent to a slit. The refined grating is engraved with thousands or even tens of thousands of notches within 1cm width. This kind of grating that uses transmitted light diffraction is called transmission grating, and there are gratings that use reflected light diffraction between two notches. Surfaces that reflect light are called reflection gratings.

Product Description:

Grating is a combination of digital technology and traditional printing technology, which can show different special effects on special films. Show the lifelike three-dimensional world on the plane, the smooth animation clips like a movie, and the incredible changing effect. A grating is a thin sheet of striped lenses. When viewed from one side of the lens, an image is seen as a thin line on the other side of the sheet, and the position of this line is determined by the viewing angle. . If these images on different lines, corresponding to the width of each lens, are arranged in order and printed on the back of the lenticular sheet, different images will be seen when viewed through the lens from different angles.

Product principle:

Gratings are also called diffraction gratings. It is an optical element that disperses (decomposes into a spectrum) light by using the principle of multi-slit diffraction. It is a flat glass or metal sheet engraved with a large number of parallel equal-width, equidistant slits (scribed lines). The number of slits in the grating is very large, generally tens to thousands per millimeter. The monochromatic parallel light passes through the diffraction of each slit of the grating and the interference between the slits, forming a pattern with very wide dark fringes and very fine bright fringes. These sharp and bright fringes are called spectral lines. The position of the spectral line varies with the wavelength. When the polychromatic light passes through the grating, the spectral lines of different wavelengths appear in different positions to form a spectrum. The light passing through the grating to form a spectrum is a common result of single-slit diffraction and multi-slit interference.

product category:

There are two types of gratings: transmissive and reflective:

1) Reflective gratings are often used in spectrometers. Each equal-width and parallel groove has the function of an optical slit. There are 1200, 1800, 2400, etc. lines per millimeter. There are hundreds of thousands of scribed lines, which can effectively split the light. In general reflective gratings, the main pole of zero-order diffraction without dispersion ability in the grating diffraction occupies 80% of the diffracted light intensity, and the light intensity becomes weak with the increase of the main pole pole, so the groove is carved into a zigzag shape. It has the ability of directional blaze, so that the ability can be concentrated in the required wavelength range. According to the manufacturing method, it can be divided into ruled grating and holographic grating. The ruled grating is made by a scoring machine on the reflective surface, while the holographic grating is made by laser interference photography.

2) The transmission grating is made by engraving a series of nicks of equal width and equal spacing on a very flat glass. Between them is equivalent to a slit, allowing light to pass through.

CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETC

Main Export Countries & Areas:

Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.

Raytekoptics Extra value added services offered:

1). Optical workcraft & process solution design;

2). Rough processing raw materials;

3). Semi finishing raw materials;

4). Fabricate custom sizes and shapes;

5). Design and supply custom coatings;

6). Modify and resurface customer supplied materials;

7). Drill holes, notch glass and provide beveled substrates;

8). Precision polish optics with non-standard aspect ratios;

Payment Method: by T/T or Western Union.

Delivery time: 7-10 days.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products with "3R" policy. For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.