Description

1. Basic data

|

ITEM |

TECHNICAL DATA |

UNIT |

VALUE |

|

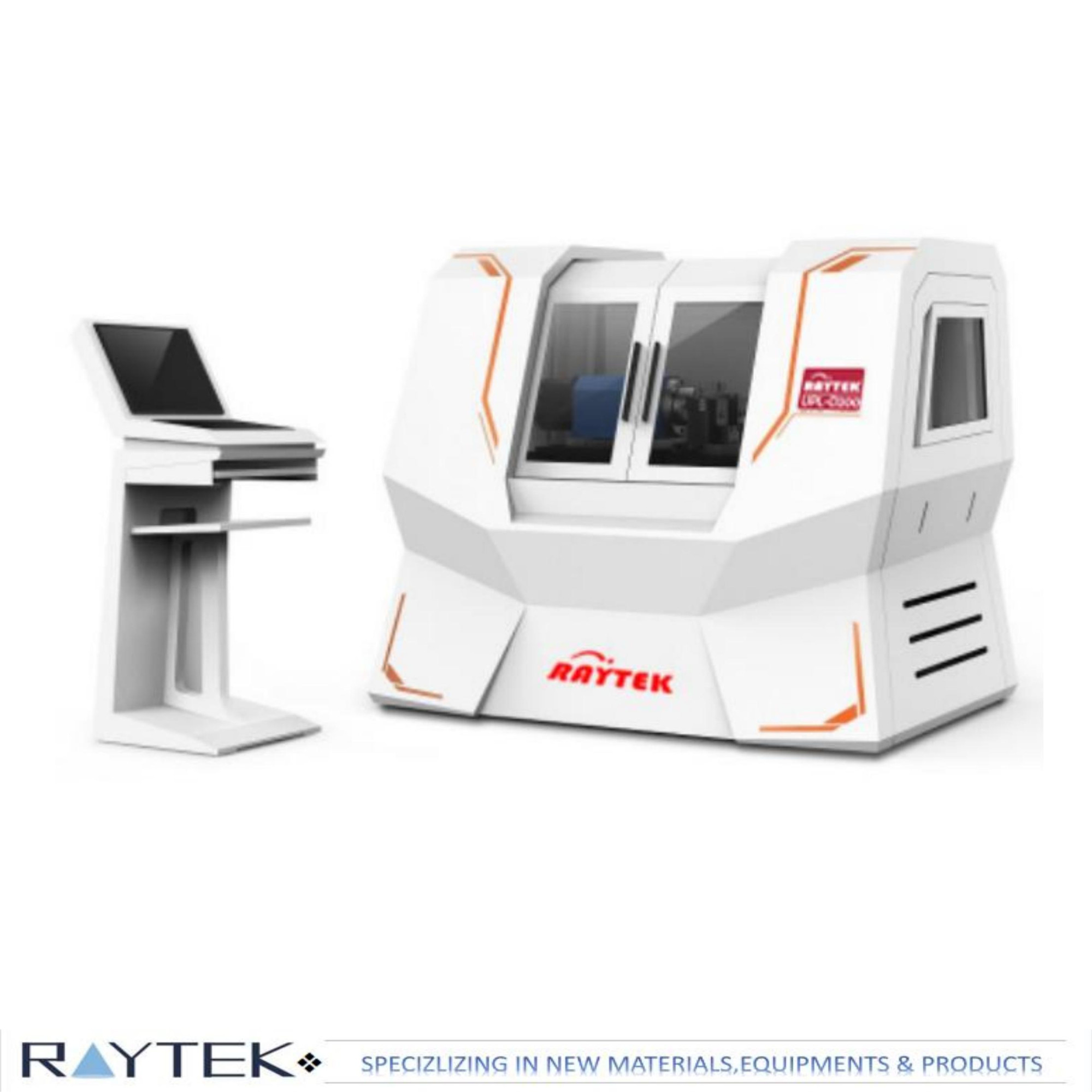

Machine Tool Builder Original of Manufacturer: Raytek Experienced: 10 years or more of manufacturing of Ultra precision machines Factory Brochure: Factory viedo through URI/CD may be shared Assessment: Attach verifiable customer reviews and provide contact details |

|||

|

1 |

Machine Base and Control |

|

|

|

1-1 |

CNC Lathe: |

- |

2 Axis |

|

1-2 |

Condition: |

- |

New |

|

1-3 |

Type: |

- |

Ultra-precision |

|

1-4 |

Machine Base: |

- |

Granite Base |

|

1-5 |

Vibration Isolation: |

- |

Air springs & integral self leveling isolators |

|

1-6 |

Controller: |

- |

Compatible & Adanced |

|

1-7 |

Programming Resolution: |

- |

<=0.1nm linear/0.0000001 Degree rotary |

|

1-8 |

File Transfer/Storage: |

- |

USD, CD,Ethernet, On Board data storage backup |

|

2 |

Performance |

|

|

|

2-1 |

Surface Roughtness: |

nm |

<=5.0nm(Ra) |

|

2-2 |

Form Accuracy: |

um |

<=0.2um |

|

3 |

Sideways and Travel |

|

|

|

3-1 |

Type: |

- |

Hydrostatic Bearing Sideways |

|

3-2 |

Travel: |

mm |

X and Z: minimum 200mm each |

|

3-3 |

Drive System: |

- |

Linear Motors |

|

3-4 |

Position Feedback Resolution: |

nm |

<0.03nm |

|

3-5 |

X-axis Straightness: Horizontal: |

um |

<=0.2um Full Travel |

|

3-6 |

Z-axis Straightness: Horizontal: |

um |

<0.2um Full Travel |

|

3-7 |

Hydrostatic Oil Supply System: |

- |

Servo Controlled Compatible System |

|

4 |

Work Holding/Positioning Spindle |

|

|

|

4-1 |

Type: |

- |

Air Bearing |

|

4-2 |

Drive Sysem: |

- |

DC Servo motors |

|

4-3 |

Spindle Speed: |

rpm |

6000rpm and above(Bi-directional) |

|

4-4 |

Ultimate Load Capacity@Spindle Nose: |

kg |

>=45kg |

|

4-5 |

Work Piece Diameter: |

|

Up to 200mm or above |

|

4-6 |

Thermal Control: |

|

Liquid Cooled Chiller with +-0.1 Celsuis Degree Accuracy or Compatible |

|

5 |

Accessories |

|

|

|

5-1 |

Tool Clamping System: |

- |

1 Equipped |

|

5-2 |

Diamond Cutting Tool(Boring, Contouring, Facing): |

- |

3 Enclosed |

|

5-3 |

Machining Coolant System: |

- |

Compatible |

|

5-4 |

Transformer: |

- |

No required |

|

***** |

|

|

|

Note: Raytek has the rights to change the configuration data and information without notice.

2. On Site Inspection & Training:

Pre-shipment Inspection at factory is compulsory(theird party inspection will not be accepted).

Test part machining & inspection will be witnessed by customer at factory before shipment.

Two weeks operation and programming for two persons at factory. All related cost and charges needed to be at the buyer’s expense.

3. Technical Documents

Elecrical and Mechanical Maintenance Manual(including Cuiruit Drawings)

Operation and Parameter Manuals for Complete System

Willl be offered enclosed with the machine packages.

Payment Method: by T/T or Western Union.

Delivery time: 12-16 weeks.

Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products with “3R” policy. For any inferior-quality products, Ruitaiphotoelectric( Raytekoptics) is responsible for return, replacement and refund.